Kovar Sealing Glass: The Ideal Sealing Solution for Relays, TO-Headers, Crystals, and Connectors

Release time:2025-06-16

This article is a buying guide for Kovar.Sealing Glass.If you need glass powder,you can get more tips form this article.

Introduction: Material Innovation for Precision Sealing

In an era where miniaturization and reliability of electronic components are paramount, glass powder sealing technology has become a critical factor in determining the performance of precision devices. Kovar Sealing Glass, in particular, has emerged as the core sealing material for products such as relays, TO-headers, crystals, and connectors, thanks to its perfect thermal expansion coefficient matching with Kovar metal (4J29). As an innovator in special glass materials, Sinopride(www.spcera.net) has successfully applied its developed Kovar sealing glass in high-end fields like automotive electronics and aerospace through precise parameter control and scenario-based solutions, providing global purchasers with sealing solutions that balance performance and cost-effectively.

I. Kovar Sealing Glass: Definition and Core Technology

1.1 What is Kovar Sealing Glass?

Kovar sealing glass is a functional sealing material specially designed for Kovar metal (iron-nickel-cobalt alloy 4J29). By precisely adjusting the composition of the glass system (such as the SiO₂-Na₂O-K₂O system), its thermal expansion coefficient achieves a high degree of matching with 4J29 metal within the range of 30-300°C. After sintering at 970-980°C, Sinopride' Kovar sealing glass forms a stress-free and high-airtight sealing layer with metal, effectively resisting harsh environments such as thermal cycling, moisture, and chemical corrosion.

1.2 Visualization of Core Parameters

|

Model |

Thermal Expansion Coefficient ×10⁻⁷/°C |

Sintering Temperature (°C) |

Density (g/cm³) |

Color Options |

Performance Benchmark |

|

SK016 |

5.0-5.5 |

970-980 |

2.25 |

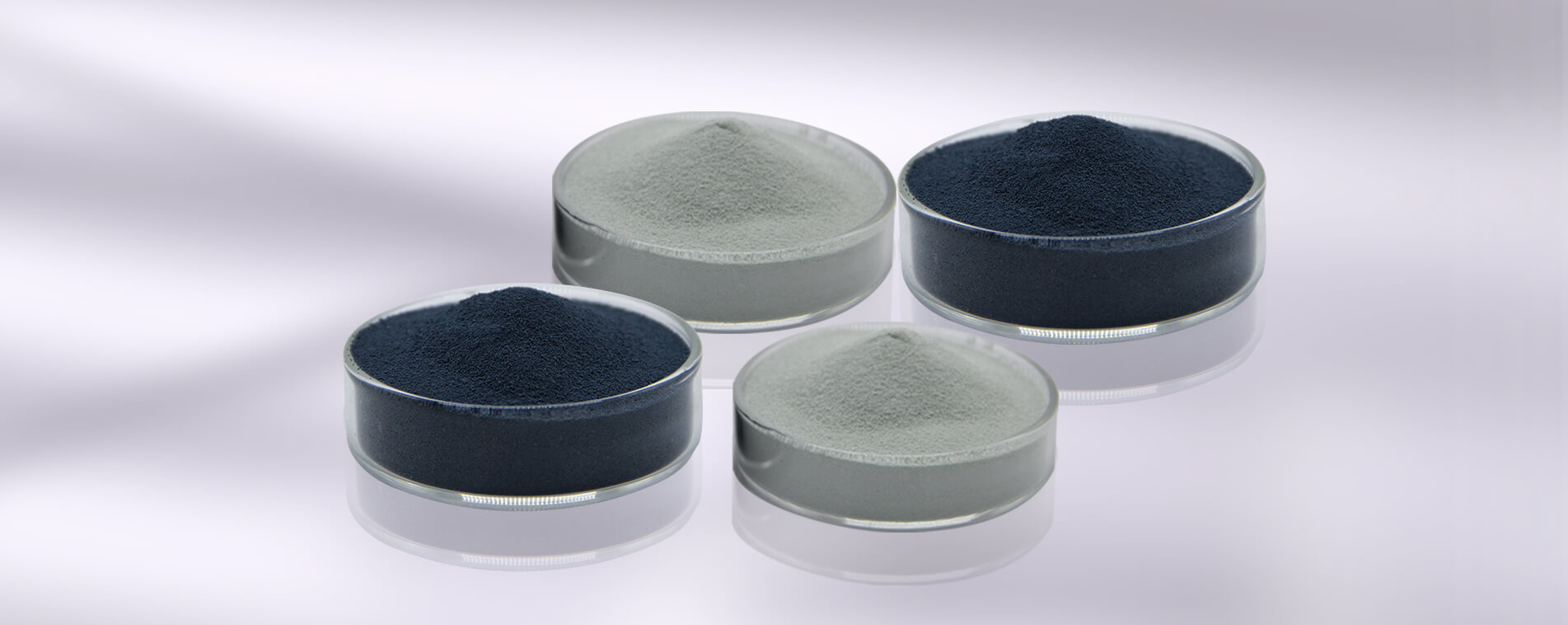

White/Green/Blue/Brown |

US 19#, BH-G/K |

Table: Technical Parameters of SK016, the Core Model of Sinopride' Kovar Sealing Glass

II. Scenario-based Applications: Full-link Sealing from Components to Systems

2.1 Relays: Safety Barriers for Automotive Electronics

2.1.1 Sealing for Automotive Power Relays

In the three-electric systems of new energy vehicles, the sealing reliability of high-voltage relays directly affects battery safety. Through thermal matching with 4J29 metal bases, Sinopride' SK016 Kovar sealing glass maintains excellent sealing performance under extreme temperature cycling, helping vehicle manufacturers reduce relay failure rates and improve product reliability.

2.1.2 Weather-resistant Sealing for Industrial Relays

In industries such as petrochemicals, explosion-proof relays need to resist humid heat and corrosive gases. The chemical stability of SK016 enables it to maintain good insulation performance in harsh environments, meeting explosion-proof certification requirements and having been batch-applied in industrial pipeline monitoring systems.

2.2 TO-Headers: Gas-tight Protection for Semiconductor Packaging

2.1.1 TO-254 Packaging for Power Devices

In the TO-header packaging of IGBT modules, the sealing layer formed by Kovar sealing glass needs to meet both electrical insulation and heat dissipation requirements. The thermal conductivity and insulation properties of SK016 help semiconductor manufacturers enhance the durability of IGBT modules and extend product service life.

2.1.2 TO-8 Packaging for Sensors

The TO-header sealing of pressure sensors needs to resist medium erosion. Sinopride' Kovar sealing glass has passed long-term medium immersion tests, with stable and reliable sealing interfaces, and has been used in the sensor packaging of construction machinery.

2.3 Crystals: The Cornerstone of Frequency Stability

2.3.1 Sealing for Oven-Controlled Crystal Oscillators

Oven-Controlled Crystal Oscillators used in 5G base stations have extremely high requirements for temperature stability. The low thermal expansion coefficient of Kovar sealing glass ensures that the crystal maintains a stable frequency within a wide temperature range, meeting communication protocol requirements.

2.3.2 Seismic Sealing for Automotive-grade Crystals

Crystals used in vehicle navigation need to pass strict mechanical vibration tests. The strong bonding force between Kovar sealing glass and metal can effectively absorb vibration energy, having passed the AEC-Q200 certification standards of the automotive electronics industry.

2.4 Connectors: Key to High-density Interconnection

2.4.1 Aerospace Circular Connectors

In aerospace equipment, Kovar sealing glass is used in high-density connectors, maintaining reliable insulation performance in vacuum and extreme temperature difference environments, meeting the harsh requirements of deep space exploration equipment.

2.4.2 High-speed Communication Rectangular Connectors

Rectangular connectors used in 5G base stations need to support high-frequency signal transmission. The dielectric properties of Kovar sealing glass ensure stable signal transmission and have been batch-supplied to communication equipment manufacturers.

III. Technical Advantages: A Cost-effective Choice for Domestic Substitution

3.1 Performance Comparison with International Brands

|

Comparison Dimension |

Sinopride SK016 |

US 19# |

Japan BH-G/K |

|

Thermal Expansion Coefficient |

5.0-5.5×10⁻⁷/°C |

5.2±0.5×10⁻⁷/°C |

5.3±0.5×10⁻⁷/°C |

|

Sintering Temperature |

970-980°C |

980-1000°C |

960-980°C |

|

Density |

2.25g/cm³ |

2.28g/cm³ |

2.26g/cm³ |

|

Price |

Cost-effective Option |

Imported Brand |

Imported Brand |

Table: Performance Comparison of Kovar Sealing Glass with International Brands

3.2 Customization Service Process

Sinopride provides a three-step customization model:

1. Requirement Diagnosis: Matching suitable basic models based on operating temperature, voltage level, and medium environment;

2. Parameter Fine-tuning: Precisely adjusting key indicators such as thermal expansion coefficient according to customer needs;

3. Process Verification: Providing samples for production line testing and assisting customers in optimizing sealing processes.

3.3 Supply Chain Assurance Capabilities

• Production Capacity: The Ganzhou base has professional production lines with a monthly capacity of 50 tons, supporting rapid delivery of urgent orders;

• Certifications: Passed multiple international quality system certifications, with products complying with environmental standards;

• Testing: Equipped with a full set of precision testing equipment to ensure stable performance of each batch of products.

IV. Procurement Selection Guide: Decision Logic from Parameters to Scenarios

4.1 Key Parameter Matching

• Operating Temperature: Select models with matching thermal expansion coefficients according to the temperature range of the application scenario, such as prioritizing SK016 for automotive engine compartment environments;

• Voltage Level: Pay attention to insulation performance in high-voltage scenarios to ensure that sealing glass meets voltage resistance requirements;

• Medium Compatibility: Customized corrosion-resistant formulas can be selected when contacting special media to ensure long-term use stability.

4.2 Cost Optimization Strategies

• Bulk Purchasing: Enjoy preferential prices to reduce unit costs;

• Solution Evaluation: Sinopride can provide cost-effective solutions based on requirements, balancing performance and cost;

• Process Collaboration: Professional teams can assist customers in optimizing production processes to reduce overall usage costs.

V. Conclusion: Making Sealing a Multiplier of Competitiveness

In the development trend of "miniaturization, high reliability, and long life" for electronic components, Kovar sealing glass has become more than just a material—it is a core technology to enhance product competitiveness. Models such as SK016 from Sinopride transform technical indicators like thermal expansion coefficient and sintering temperature into quantifiable industrial value through a model of "parameter visualization + scenario-based verification", providing reliable sealing guarantees for precision components such as relays and TO-headers.

If you are seeking sealing solutions that can operate stably in extreme environments, welcome to contact Sinopride to obtain customized Kovar sealing glass solutions.