The Invisible Hero in Hermetic Sealing:

Featured Product

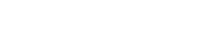

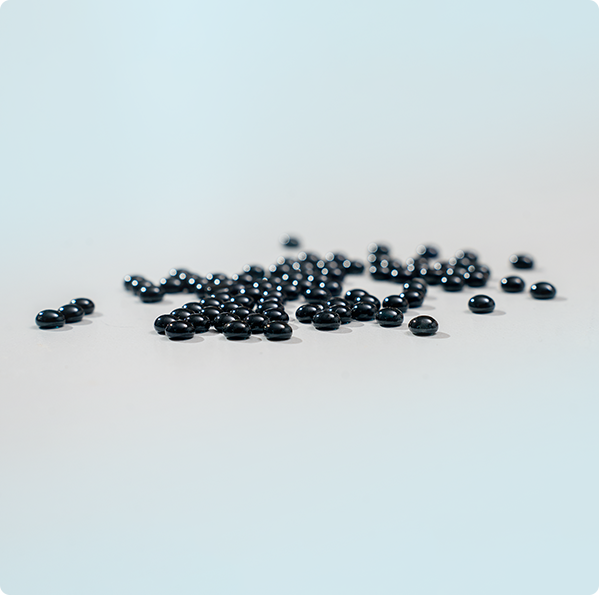

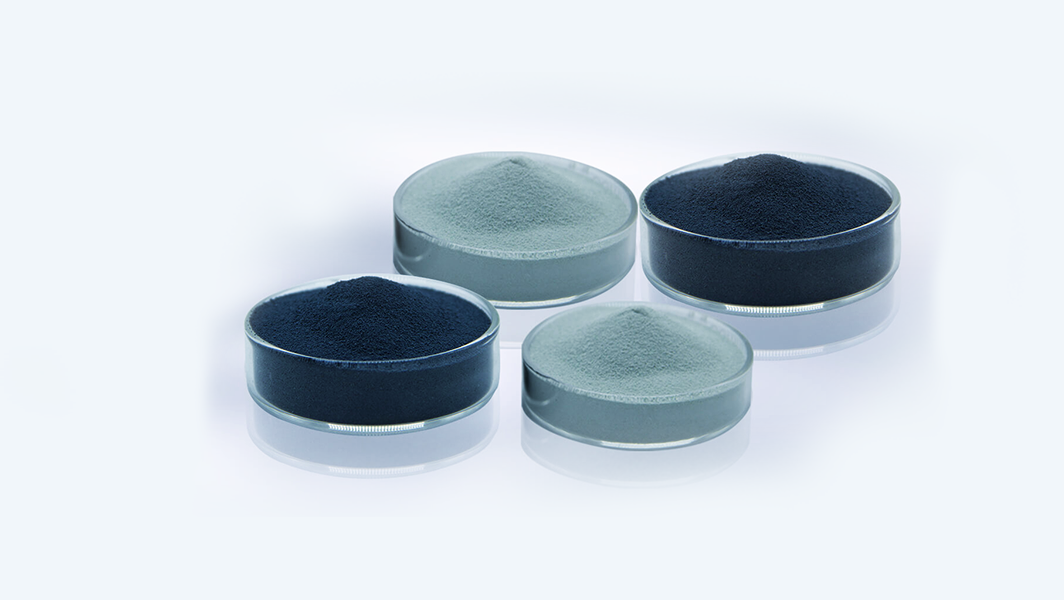

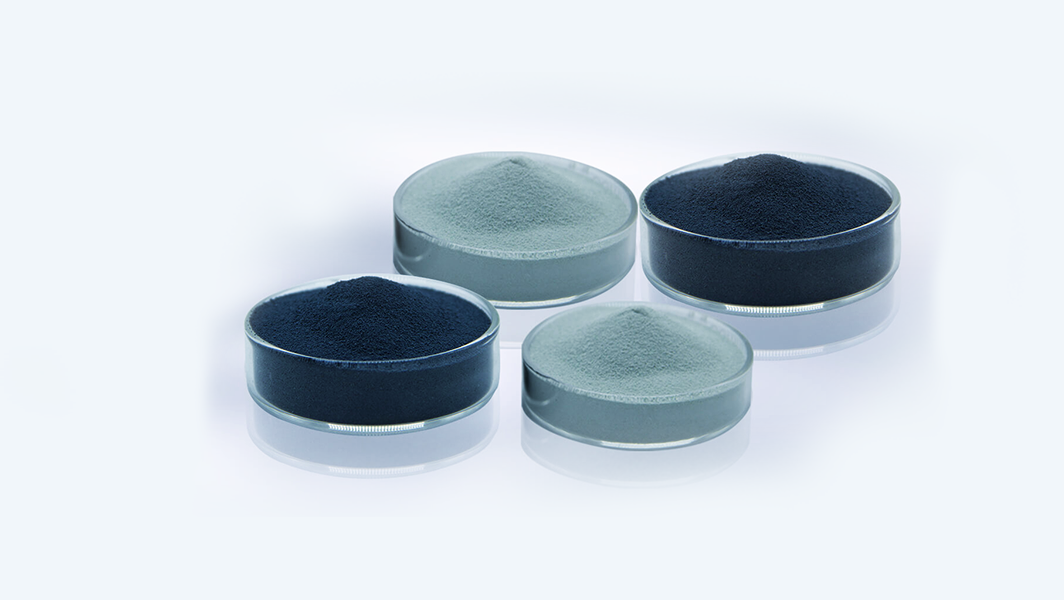

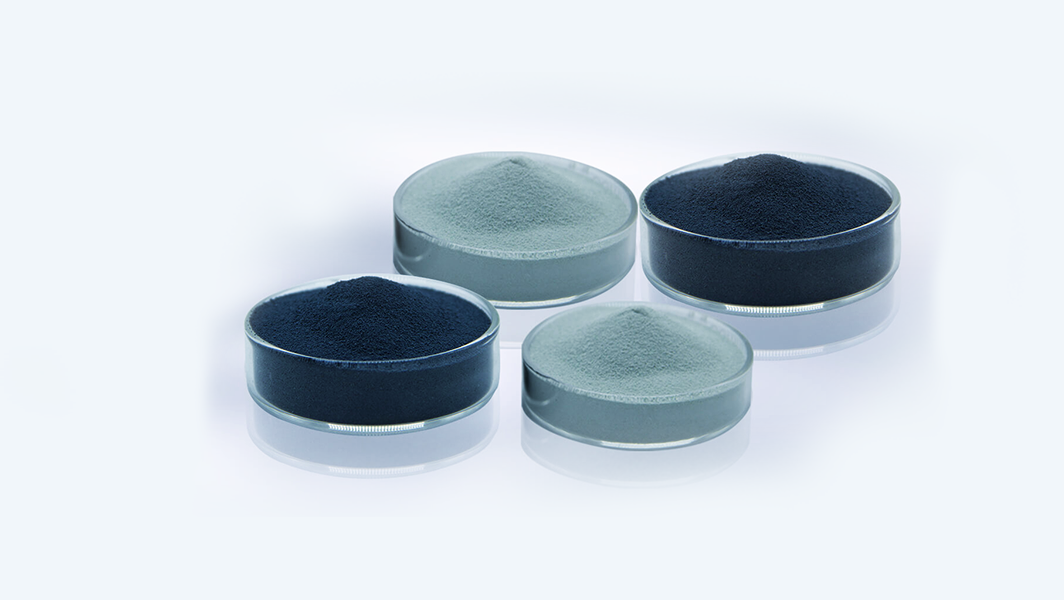

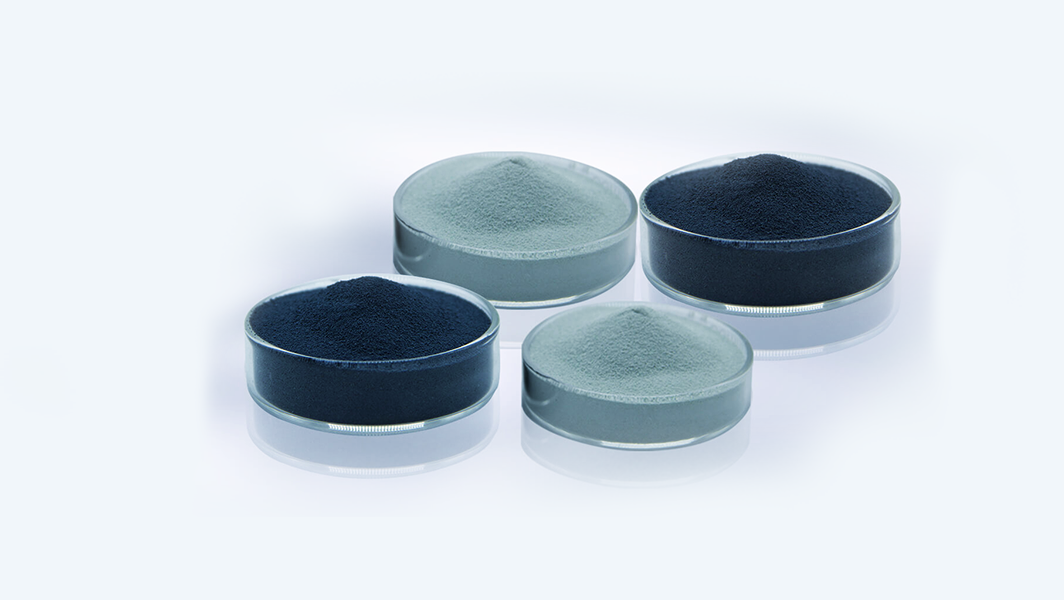

Low-Temperature Glass Preforms

Designed for applications where high temperatures could damage sensitive components, our low-temperature glass preforms melt and form a hermetic seal at temperatures much lower than traditional glass materials.

Key Consideration: Sealing Glass Characteristics

Glass Specifications & Applications |

||||||

| No. | Code | Glass Composition | Density g/cm3 |

Sintering Temperature Tm/℃ |

CTE/10-6(30-300℃) | Color |

| LTCC | LP080 | P2O5-SnO-ZnO | 3.85 | vacuum 560 | 13.4±0.5 | Black |

| LC-1 | Bi2O3-B2O3-ZnO | 6.60 | vacuum 600 | 11.7±0.5 | Black | |

The Application Areas of Products

-

Vacuum Bottle

-

Glass Paste

-

Ceramic Substrate Glaze

How Can Sealing Glass Preforms

Make the Difference?

Precision-Engineered Shapes

Our glass solder preforms are meticulously crafted into a variety of shapes - rods, tubes, discs, and more - tailored to meet the exact specifications of your sealing needs.

Customized Glass Composition

Each preform is composed of specially formulated glass, designed to match the thermal expansion properties of different metals, ensuring a perfect seal every time.

Uniform Quality and Consistency

State-of-the-art manufacturing processes guarantee uniformity in size, shape, and composition, delivering unparalleled consistency across batches.

Glass Preform Manufacturing:

Process and Key Considerations

Process and Key Considerations

- Raw Material Selection

- Batch Preparation

- Forming the Preforms

- Precision Shaping

- Quality Control

- Packaging and Shipping

Choose Sinopride:

A Premium Glass Preform Manufacturer from China

We are a premier hermetic sealing glass manufacturer in China specializing in the research and production of high-quality sealing glass powder and related products and solutions. Our goal is to protect critical components from moisture, dust, thermal variations, and shocks for optimal performance and longevity in demanding applications. Choose us for our shared commitment to delivering products that embody precision, durability, and unparalleled quality.

30+

Years of Experience

20+

Members of QC Team

11+

Members of R&D Team

600+

Annual Production in Tonnes

39+

Patents Granted

Let's Build Your

Product

Product