30+

Years of Experience

20+

Members of QC Team

11+

Members of R&D Team

600+

Annual Production in Tonnes

39+

Patents Granted

Manufacturing Capacity

Welcome to Sinopride, we offer comprehensive solutions in metal-glass/ceramic sealing glass powder and hermetic sealings. Our cutting-edge manufacturing facility is equipped with 7 glass to metal seal production lines, 2 glass granulation powder production lines, and an advanced electroplating line.

Production Capacity

Sinopride boasts a robust production capacity, featuring 15 crucible melting furnaces and a continuous melting furnace. Each crucible furnace yields a daily glass output ranging from 150 to 200kg, while the continuous furnace can achieve a daily output of 700 to 800kg. In total, our daily production capacity reaches 1700 to 2000kg of glass.

Powder Processing

Our factory is equipped with 8 horizontal ball mills designed to grind powder balls to less than 10 microns. With a daily processing capacity ranging from 1000 to 1500kg, we ensure efficient and precise powder processing.

Production Equipment

Sinopride features 2 powder granulation towers and 1 experimental granulation tower, facilitating a daily production of 1500kg of glass granulation powder.

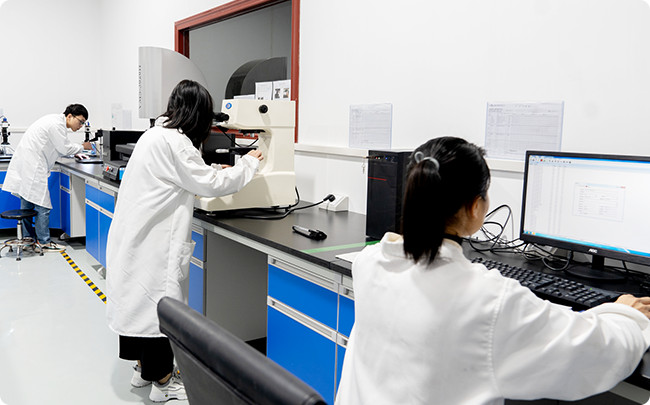

Quality Control

At Sinopride, the quality of our metal-glass/ceramic products is our primary focus. We adhere to the highest industry standards, employing a rigorous Quality Management System (QMS) to ensure top-notch performance in sealing glass powder, hermetic sealing, and LTCC dielectric glass material development. Trust Sinopride for unparalleled quality and reliability.

Successful Cooperations

Let's Build Your

Product

Product