Featured Product

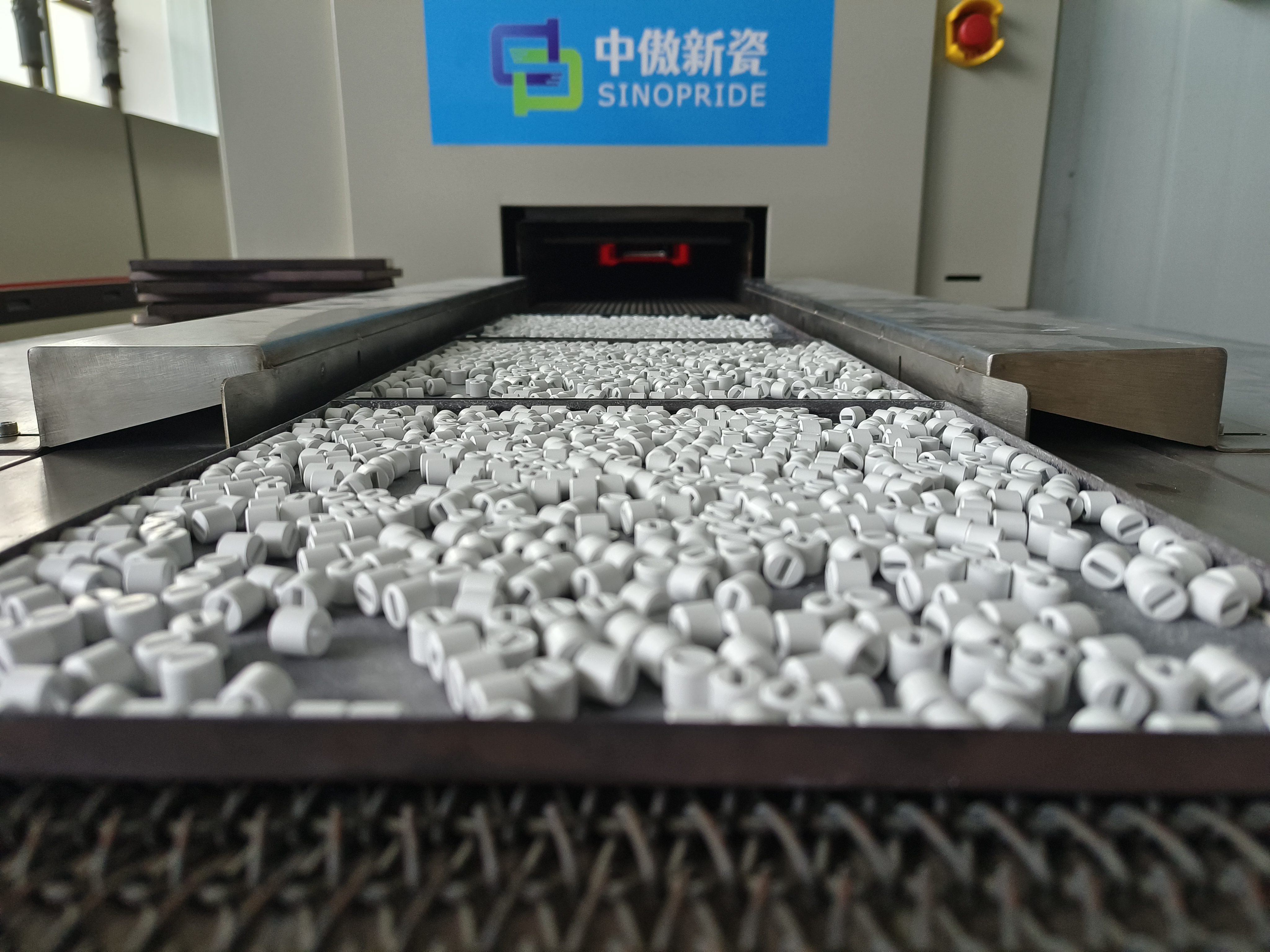

O2S Gasket

Specifications & Applications |

|||||

| Code | Ceramic Composition | weight tolerance | operating temperature | leakage rate | Remark |

| SH100 | O2S Gasket | ±2% | ≤800℃ | <0.1 ml/min | No sintering |

| SH035 | O2S Gasket | ±2% | ≤800℃ | <0.1 ml/min | 630℃ sintering |

The Application Areas of Products

-

Nitrogen-oxygen Sensor for Vehicles

-

Oxygen Sensor for Vehicles

-

Motorcycle Oxygen Sensor

-

Mature and Stable Formula

Our oxygen sensor gaskets have been continuously supplied for over five years, utilizing a formula that has undergone rigorous testing and long-term market validation. This mature and stable composition ensures that the gaskets perform reliably even in the most challenging environmental conditions. The proven formula provides consistent sealing, preventing leaks and maintaining the integrity of the sensor's performance over time.

-

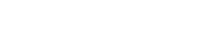

Unique Granulation Process

At Sinopride, we employ a unique granulation process that results in oxygen sensor gaskets with uniform particle size and shape. This meticulous process not only enhances the visual quality of the gaskets but also significantly improves their compressibility and stability during use. The uniform granules ensure that the gaskets fit perfectly into the sensor assembly, providing a dependable seal that contributes to the overall efficiency and accuracy of the oxygen sensor.

-

Precision Tolerance Control

Our advanced manufacturing capabilities allow us to achieve precision tolerance control within ±2%. This exceptional level of accuracy ensures that each gasket is produced to exact specifications, offering a perfect fit for various sensor designs. The tight tolerance control minimizes the risk of performance degradation or failure due to improper sealing, thereby extending the lifespan and reliability of the oxygen sensor.

-

OEM Approved

Sinopride's oxygen sensor gaskets have been extensively tested and validated by leading OEMs. These gaskets have passed rigorous testing protocols, proving their effectiveness in real-world applications. The approval from top-tier OEMs is a testament to the superior quality, durability, and reliability of our products, making them a trusted choice for critical applications in automotive, industrial, and environmental sectors.

We Specialize in:

Oxygen Sensor Gaskets

-

Ensuring Accurate Oxygen Measurement

Reliable sealing is crucial in oxygen sensors, as it directly impacts the sensor's ability to accurately measure oxygen levels. Any leakage or compromise in the seal can introduce external elements into the sensor, leading to incorrect readings. Accurate oxygen measurement is vital for optimal engine performance, fuel efficiency, and emission control, making the quality of the seal a key factor in the sensor's effectiveness.

-

Protection Against Harsh Environments

Oxygen sensors operate in demanding environments, exposed to extreme temperatures, high pressures, and corrosive substances. A robust seal acts as a protective barrier, safeguarding the internal components of the sensor from these harsh conditions. This protection is essential to maintain the sensor's functionality over time, preventing damage that could lead to sensor failure or reduced performance.

-

Enhancing Sensor Longevity and Reliability

The longevity and reliability of an oxygen sensor are heavily dependent on the integrity of its seal. A durable seal prevents contamination and degradation, ensuring that the sensor continues to operate effectively throughout its lifespan. By maintaining a secure and consistent seal, the sensor remains reliable, reducing the need for frequent replacements and ensuring continuous, accurate monitoring.

-

Critical for Engine Control and Emission Reduction

A reliable seal ensures that the sensor provides precise data to the engine management system, enabling it to adjust fuel-air mixtures for maximum efficiency and minimal environmental impact. Without a dependable seal, the sensor's ability to contribute to emission control is compromised, affecting both vehicle performance and compliance with environmental regulations.

1.Composition and Material

Formulation: Developed with advanced inorganic materials, ensuring optimal compatibility and performance in oxygen sensor applications.

Granulation Process: Unique granulation technique to ensure uniform particle size and shape, enhancing the sealing integrity.

2.Dimensional Tolerances

Shape Consistency: High precision in the shape of the gasket to ensure proper alignment and sealing within the oxygen sensor assembly.

3.Temperature Resistance

Thermal Stability: Maintains structural integrity and sealing effectiveness under extreme thermal cycling conditions.

4.Mechanical Properties

Elasticity: Sufficient elasticity to accommodate slight movements or shifts within the sensor housing without compromising the seal.

5.Compliance and Validation

Validation: Rigorously tested and validated by leading automotive manufacturers to ensure reliability and performance under real-world conditions.

6.Packaging and Availability

Customization: Custom formulations and sizes available upon request to meet specific application needs.

Product