Exploring the Best Glass to Metal Seal Manufacturers in the US

Release time:2025-11-14

Glass to metal seals play a crucial role in industries requiring high-performance and durable materials, including aerospace, electronics, medical devices, and automotive sectors. This sealing process ensures hermeticity and reliability, offering solutions where traditional mechanical seals may fail. The US hosts some of the best manufacturers in this field, each contributing to innovative sealing technologies. In this blog, we explore the glass to metal sealing process, types of seals, key design considerations, market trends, and highlight top US manufacturers driving the industry forward.

What is a glass-to-metal seal:An overview of the sealing process

-What is the sealing process?

-How are glass to metal seals made?

What are the types of glass metal seals used for?

-What is a glass-to-metal seal preform?

-What is glass to metal feed through?

Glass to metal seal design guide: key considerations for optimal performance

Exploring the glass-to-metal seals market: trends and insights

Top glass to metal seal manufacturers in the US

Glass to metal sealing technology: innovations driving the industry forward

What is a Glass-to-Metal Seal: An Overview of the Sealing Process

What is the Sealing Process?

A glass to metal seal is a method of bonding a glass material to a metal surface to create a tight, hermetic seal. This process is critical in applications that require protection against contaminants, moisture, or gases. The sealing process typically involves carefully heating the glass and metal materials to high temperatures, allowing the glass to soften and bond with the metal. This bond ensures the components are sealed in a way that is both durable and long-lasting.

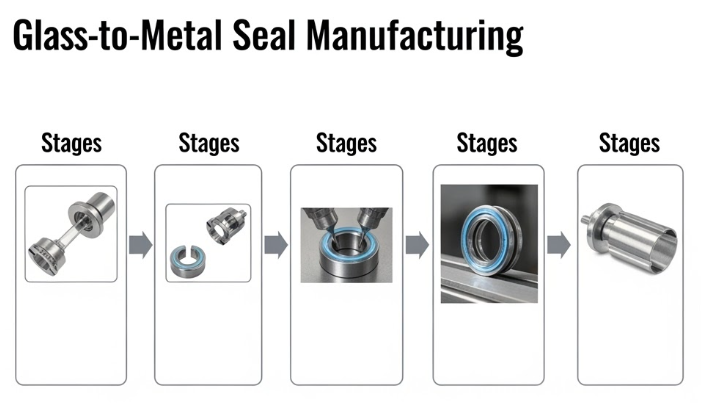

The sealing process involves several key steps:

1.Heating: Both the glass and metal components are heated to high temperatures in a furnace.

2.Fusing: As the glass softens, it flows into the microscopic pores of the metal, forming a mechanical and chemical bond.

3.Cooling: The components are slowly cooled to ensure the bond is strong and stable.

How Are Glass to Metal Seals Made?

The glass to metal sealing process can be broken down into three primary methods:

1.Direct Sealing: Involves using a pre-formed glass that is placed directly onto a metal part, and the bond is formed through heat.

2.Preform Sealing: A glass preform (a small piece of glass) is created and placed inside a metal housing, and then heated to fuse the two materials.

3.Compression Sealing: In this process, the metal is compressed around the glass, forming a tight seal.

What Are the Types of Glass Metal Seals Used For?

What is a Glass-to-Metal Seal Preform?

A glass-to-metal seal preform is a specially designed piece of glass used in the sealing process. It is often a cylindrical or disk-shaped object made of a specific type of glass that can form a reliable bond with metal components. These preforms are particularly useful when creating complex shapes and structures. Preforms are molded or shaped to fit the precise dimensions required for a particular application, ensuring a perfect seal when the sealing process is complete.

Glass-to-metal preforms are used widely in industries where high performance and precision are critical, such as in aerospace, medical devices, and electronic components.

What is Glass to Metal Feed Through?

A glass to metal feed-through is a specialized type of glass to metal seal used to provide a sealed pathway for electrical or fluid connections between an enclosed system (such as a vacuum or pressurized vessel) and the external environment. Feed-throughs are used in applications such as vacuum tubes, high-voltage electronics, and sensors where a sealed, insulated connection is needed between the inner and outer components. These feed-throughs are essential for preventing contamination, maintaining a stable environment, and ensuring the safety of electrical connections.

Glass to Metal Seal Design Guide: Key Considerations for Optimal Performance

When designing a glass-to-metal seal, there are several critical factors that manufacturers must consider to ensure optimal performance and reliability of the final product:

1.Material Compatibility: The glass and metal must be compatible in terms of thermal expansion, chemical properties, and mechanical strength. If the materials do not expand and contract at similar rates, stress may cause the seal to fail.

2.Temperature Resistance: Glass-to-metal seals are often used in extreme environments, requiring materials that can withstand high temperatures without degradation. Manufacturers must choose glasses and metals that can handle the temperatures they will be exposed to.

3.Pressure and Environmental Factors: The seal must maintain its integrity under varying pressure conditions. Seals used in vacuum systems, for example, need to ensure airtightness even under extreme pressure fluctuations.

4.Seal Type: Whether using a compression seal, feed-through, or preform, selecting the right type of seal is crucial for the success of the application.

5.Manufacturing Precision: The precision of the sealing process is key to ensuring that the seal is durable and effective. Any inconsistencies in the manufacturing process can lead to leakage or failure.

Exploring the Glass-to-Metal Seals Market: Trends and Insights

The glass-to-metal seals market in the US is experiencing steady growth, driven by innovations in materials and manufacturing technologies. Industries that rely on highly durable and reliable seals—such as aerospace, automotive, and electronics—are pushing demand for specialized glass-to-metal sealing solutions. Key market trends include:

1.Demand for Miniaturization: As technology advances, there is an increasing need for smaller, more efficient seals, particularly in electronics and medical devices.

2.Sustainability and Environmental Focus: With growing concerns over environmental impact, many manufacturers are focusing on more sustainable production methods and the use of eco-friendly materials.

3.Technological Advancements: New sealing technologies, including automated sealing and advances in precision engineering, are helping to improve the quality, cost-effectiveness, and speed of production.

Top Glass to Metal Seal Manufacturers in the US

In the US, several manufacturers stand out in the glass to metal seal industry for their innovation, product quality, and applications across a wide range of sectors. Here are some of the leading players:

|

Manufacturer |

Key Products |

Features |

Applications |

|

CeramTec |

Glass-to-metal seals, feed-throughs |

Advanced materials, custom solutions |

Aerospace, electronics, medical devices |

|

Advanced Glass Industries |

Custom glass-to-metal seals, preforms |

High precision, specialized for high temperatures |

Aerospace, automotive, industrial systems |

|

Schott North America |

Glass-to-metal sealing components |

Extensive product range, precision engineering |

Medical technology, electronics |

|

Teledyne Microwave Solutions |

Glass feed-throughs, custom seals |

High-performance seals for sensitive applications |

Aerospace, defense, communications |

|

Minitube |

Glass-to-metal feed-throughs, connectors |

Durable and cost-effective designs |

Medical, telecommunications, industrial |

1.CeramTec

(1)Key Products: CeramTec specializes in glass-to-metal seals and feed-throughs. These are essential components for creating hermetic seals between glass and metal in various applications.

(2)Features: The company uses advanced materials and offers custom solutions tailored to meet specific requirements. CeramTec focuses on providing high-quality seals with excellent performance in demanding environments.

(3)Applications: CeramTec's products are used in aerospace, electronics, and medical devices. Their solutions are ideal for applications that require robust, reliable sealing in sensitive environments like space exploration, electronics, and medical technologies.

2.Advanced Glass Industries

(1)Key Products: Advanced Glass Industries manufactures custom glass-to-metal seals and preforms. Preforms are essentially semi-finished parts used to create the final glass seals.

(2)Features: Known for high precision, Advanced Glass Industries specializes in seals designed to withstand high-temperature environments. Their ability to customize seals ensures they meet the needs of various industrial applications.

(3)Applications: These products are primarily used in aerospace, automotive, and industrial systems. The seals are designed to provide long-lasting durability and reliability in high-stress environments, such as in engines, sensors, and other high-temperature applications.

3.Schott North America

(1)Key Products: Schott North America offers glass-to-metal sealing components that are integral in creating strong and durable seals between glass and metal.

(2)Features: Schott is known for its extensive product range and precision engineering. They provide seals that are highly reliable and engineered to meet stringent performance standards across various industries.

(3)Applications: Their products find application primarily in medical technology and electronics. Schott’s solutions are ideal for devices that require precise and dependable seals, such as in diagnostic equipment, electronic devices, and other critical medical applications.

4.Teledyne Microwave Solutions

(1)Key Products: Teledyne manufactures glass feed-throughs and custom seals. These are crucial for creating airtight and durable seals for sensitive applications.

(2)Features: Teledyne focuses on high-performance seals, specially designed for sensitive applications where reliability and accuracy are essential. The company offers custom solutions to meet the specific needs of complex systems.

(3)Applications: Their products are primarily used in aerospace, defense, and communications. The seals are designed to ensure long-term reliability in high-stakes industries, including military technology, satellite communications, and other aerospace applications.

5.Minitube

(1)Key Products: Minitube produces glass-to-metal feed-throughs and connectors, which are components used for sealing and connecting different parts of an electronic or mechanical system.

(2)Features: Minitube is known for providing durable and cost-effective designs. Their products are designed to ensure long-lasting performance while being economically viable.

(3)Applications: Minitube’s products are applied in the medical, telecommunications, and industrial sectors. They provide a cost-efficient solution for industries requiring high-quality seals for sensitive equipment, including medical instruments, telecom devices, and industrial machinery.

These companies each specialize in different aspects of glass-to-metal sealing technology and serve various industries with their unique product offerings. They focus on high precision, customization, and durability to meet the rigorous demands of sectors like aerospace, medical technology, electronics, and more.

Each of these manufacturers brings unique capabilities to the table, whether it’s CeramTec’s focus on custom solutions, Schott’s precision engineering, or Teledyne’s high-performance seals for sensitive aerospace applications.

Glass to Metal Sealing Technology: Innovations Driving the Industry Forward

The glass to metal sealing technology has seen significant advancements in recent years, driven by innovations in materials science and manufacturing techniques. Some of the most notable developments include:

1.Automation in Manufacturing: Automated systems are increasingly used to improve the precision and consistency of glass-to-metal seals. This reduces human error and enhances production efficiency, enabling manufacturers to meet the growing demand for high-performance seals.

2.Material Advancements: Researchers are continuously developing new glass and metal materials that can withstand higher temperatures, harsher environments, and more demanding applications. For example, special alloys and glass compositions are being created for use in extreme environments like outer space.

3.Sustainability Focus: As demand for more sustainable solutions grows, manufacturers are incorporating eco-friendly materials and energy-efficient production methods into the sealing process.

4.Miniaturization: As electronic devices become smaller and more compact, the need for miniature glass-to-metal seals has increased. This has led to innovations in micro-sealing technologies, allowing manufacturers to produce smaller, more efficient seals that are critical for high-performance devices.

These technological advancements are helping to push the limits of what’s possible in glass-to-metal sealing, improving performance and expanding the range of applications.

Conclusion

Glass to metal seals are a fundamental component of many high-performance systems across industries. The US is home to several leading manufacturers who are continuously innovating to meet the evolving demands of these industries. From aerospace to medical devices, glass-to-metal seals are integral to ensuring the safety, reliability, and longevity of critical systems. By staying ahead of trends in materials and manufacturing technology, these manufacturers are driving the industry forward, ensuring that glass to metal seals remain a key part of modern engineering solutions.

Recommended reading

1.What is a glass to metal seal?

2.Top 5 Glass to Metal Seal Manufacturers in the World 2025

3.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors