Innovative Glass-to-Metal Sealing Enhances Oxygen Sensor Gasket Reliability in New Energy Vehicles

Release time:2025-09-29

In the fast-growing field of new energy vehicles (NEVs), ensuring the reliability and efficiency of key components is paramount. One such critical component is the oxygen sensor, which plays a vital role in regulating the engine's fuel efficiency and emission control. To enhance the performance and longevity of oxygen sensors, glass-to-metal sealing technology is becoming increasingly important. This innovative sealing solution ensures that the oxygen sensor gasket maintains its durability, gas-tightness, and resistance to extreme conditions. In this article, we will explore the fundamentals of glass-to-metal sealing, its application in oxygen sensor gaskets, and why it's crucial for the NEV industry.

What is a Glass-to-Metal Seal?

-What Element is Used for Glass-to-Metal Seals?

-What is the Glass-to-Metal Sealing Process?

-What Are the Advantages of Metal to Glass Seal?

What is the Main Function of the O2 Sensor Gasket?

-What is the Purpose of an Oxygen Sensor in a Vehicle?

-Sealing Requirements for Oxygen Sensors

Application of Glass-to-Metal Hermetic Seal Technology in 02 Sensor Gaskets

-Sealing Solutions for Oxygen Sensor Gaskets

-The Core Role of Sealing Powder Ring in Oxygen Sensor Gasket

The Significance of Glass-to-Metal Seals Technology to the New Energy Vehicle Industry

Why Choose SPCERA Glass-to-Metal Seal Manufacturers?

-Using Proprietary Ceramic Sealing Powder

-Mature Glass-to-Metal Sealing Process

-Glass-to-Metal Seal Design Possibilities

FAQs

-What Happens When the O2 Sensor Goes Bad?

-What is the Glass-to-Metal Seal Market?

-What is a Sealed Glass?

What is a Glass-to-Metal Seal?

What Element is Used for Glass-to-Metal Seals?

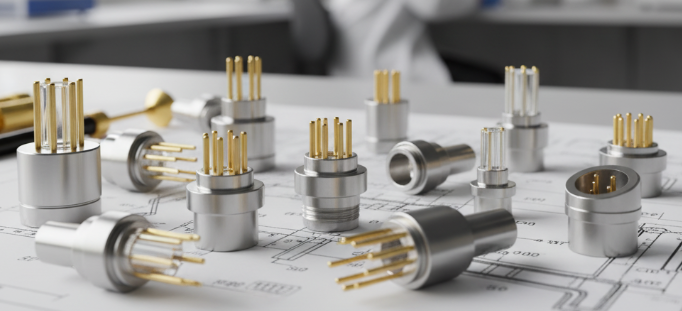

A glass-to-metal seal is a unique and highly effective bonding technology that combines glass with metal to create a durable, gas-tight seal. The key to a successful glass-to-metal seal is the compatible expansion rates between the metal and the glass. Common metals used for these seals include stainless steel, nickel, and Kovar, while the glass typically contains compounds such as borosilicate or silica. These materials are chosen for their ability to withstand high temperatures, pressures, and corrosive environments, making them ideal for applications in harsh conditions such as those found in automotive components.

What is the Glass-to-Metal Sealing Process?

The glass-to-metal sealing process begins with a precise combination of metal components and specialized glass formulations. These materials are heated together to a specific temperature, allowing the glass to melt and bond with the metal, creating an airtight seal. The result is a strong, hermetic seal that can maintain its integrity under extreme conditions, such as high temperatures, moisture, and mechanical stress. This process is widely used in industries where reliability and performance are critical, including aerospace, automotive, and medical devices.

What Are the Advantages of Metal to Glass Seal?

Glass-to-metal seals provide several advantages, particularly in high-performance applications like oxygen sensor gaskets:

1.Excellent gas-tightness: The seal prevents gas leakage, ensuring the sensor's accuracy and longevity.

2.High temperature and pressure resistance: It can withstand extreme thermal and pressure variations, making it ideal for automotive and industrial use.

3.Corrosion resistance: The seal offers superior protection against corrosion, ensuring durability even in harsh environments.

4.Longevity: The robust seal ensures a longer lifespan for components, reducing maintenance costs and extending the service life of the oxygen sensor.

What is the Main Function of the O2 Sensor Gasket?

What is the Purpose of an Oxygen Sensor in a Vehicle?

The oxygen sensor is one of the most important components in a vehicle's emission control system. It measures the level of oxygen in the exhaust gases and sends this data to the vehicle's engine control unit (ECU). Based on this information, the ECU adjusts the air-fuel ratio to optimize fuel combustion. By ensuring efficient combustion, the oxygen sensor helps improve fuel efficiency and reduce harmful emissions, which is especially critical for meeting environmental standards in new energy vehicles.

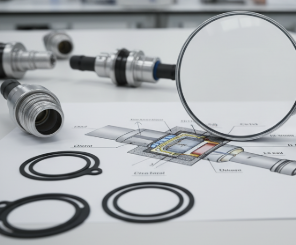

Sealing Requirements for Oxygen Sensors

Oxygen sensor gaskets are designed to maintain the gas-tight integrity of the sensor, ensuring no leakage of exhaust gases. The gasket provides the crucial sealing between the sensor housing and the engine or exhaust system. The sealing material must be capable of withstanding:

1.High operating temperatures (up to 1000°C)

2.Pressure fluctuations

3.Chemical exposure (exhaust gases containing CO, CO2, and nitrogen)

4.Mechanical stress due to vibrations and expansion

The glass-to-metal sealing technology offers a perfect solution for these requirements by providing a durable, long-lasting seal that can handle the extreme conditions encountered by oxygen sensors in NEVs.

Application of Glass-to-Metal Hermetic Seal Technology in 02 Sensor Gaskets

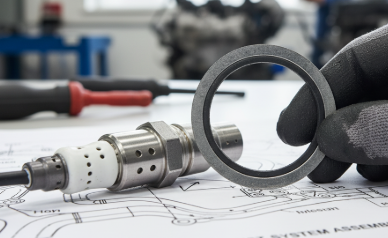

Sealing Solutions for Oxygen Sensor Gaskets

When it comes to sealing oxygen sensor gaskets, glass-to-metal sealing technology plays an integral role in ensuring the gasket's effectiveness. The sealing technology ensures that the gasket remains gas-tight, even when exposed to extreme temperatures and pressures. This is crucial in maintaining the performance and lifespan of the oxygen sensor, which directly affects fuel efficiency and emission levels.

The glass-to-metal seal also protects the oxygen sensor from moisture, dust, and other contaminants, which can negatively impact sensor accuracy and reliability. The ability of glass-to-metal seals to withstand thermal cycles—the repetitive heating and cooling in a running engine—makes them ideal for ensuring long-term functionality in automotive environments.

The Core Role of Sealing Powder Ring in Oxygen Sensor Gasket

A crucial element in the application of glass-to-metal seals in oxygen sensor gaskets is the sealing powder ring. This component is made of ceramic or glass powder that plays a vital role in maintaining the airtight seal during high-temperature operation. The powder is placed between the metal parts of the sensor and the sealing surface, then heated to create a strong bond. The powder ensures the proper sealing between the two materials, providing enhanced gas-tightness and ensuring the long-term durability of the sensor gasket.

The Significance of Glass-to-Metal Seals Technology to the New Energy Vehicle Industry

In the new energy vehicle (NEV) industry, meeting stringent environmental standards is a significant challenge. Oxygen sensors are essential for maintaining low emissions and optimal fuel efficiency. By utilizing glass-to-metal sealing technology, manufacturers can enhance the reliability and performance of these sensors.

This technology also enables NEVs to achieve higher fuel efficiency, reduce emissions, and comply with increasingly strict environmental regulations. As the demand for sustainable vehicles rises, the role of glass-to-metal seals in ensuring sensor reliability and long-term performance becomes even more critical.

Why Choose SPCERA Glass-to-Metal Seal Manufacturers?

Using Proprietary Ceramic Sealing Powder

SPCERA specializes in the development and application of ceramic sealing powders that improve the strength and durability of glass-to-metal seals. These proprietary powders enhance the sealing performance of oxygen sensor gaskets, ensuring long-term reliability and minimizing the risk of seal failure.

Mature Glass-to-Metal Sealing Process

With years of experience in glass-to-metal sealing technology, SPCERA has perfected the sealing process. Their advanced sealing techniques ensure that each gasket is manufactured to the highest standards, providing superior gas-tightness and durability.

Glass-to-Metal Seal Design Possibilities

SPCERA offers customized design solutions for glass-to-metal seals, allowing manufacturers to meet specific requirements for their oxygen sensor gaskets. Whether it’s temperature, pressure, or chemical resistance, SPCERA’s expert team can tailor the seal to suit a wide range of applications.

FAQs

What Happens When the O2 Sensor Goes Bad?

When an oxygen sensor malfunctions, it can lead to poor fuel efficiency, increased emissions, and engine performance issues. A faulty sensor may cause the engine to run too rich (excessive fuel) or too lean (insufficient fuel), leading to higher emissions and decreased fuel economy.

What is the Glass-to-Metal Seal Market?

The glass-to-metal seal market refers to the industry that manufactures seals using glass and metal for high-performance applications. These seals are essential for industries like automotive, aerospace, electronics, and medical devices, where reliable sealing is crucial.

What is a Sealed Glass?

Sealed glass refers to glass that has been hermetically sealed with metal to create a gas-tight bond. This technology is used in applications where airtight and durable seals are essential, such as in oxygen sensors, medical devices, and vacuum tubes.

Conclusion

Glass-to-metal sealing is an innovative and highly reliable technology that enhances the performance and longevity of oxygen sensor gaskets in new energy vehicles. By providing a strong, durable, and gas-tight seal, this technology ensures that oxygen sensors can function accurately and efficiently, even in the harshest conditions. As the demand for environmentally friendly vehicles grows, the role of glass-to-metal seals in ensuring the reliability of critical components like oxygen sensors will continue to be vital for the NEV industry.