The Ultimate Buying Strategy for Glass-to-Metal Seals

Release time:2025-09-25

Glass-to-metal seals (GMS) are specialized joints used to bond glass to metal, providing a hermetic seal that ensures airtightness and reliability in demanding environments. These seals are made through a process of heating, bonding, and cooling glass and metal components. Common materials used include nickel, Kovar, and stainless steel for metals, and lead-free or borosilicate glass for optimal performance.

What is a glass to metal seal?

-What is the definition of a glass to metal sealing?

-How are glass to metal seals made?

Understanding Glass-to-Metal Seals Types and Applications

metal to glass seal Material Selection Guide

-Choose the right metal material

-What is the most common material in glass?

-The combination of glass and metal

Comprehensive Cost and Pricing Analysis for Glass-to-Metal Seals Procurement

Advantages of glass-to-metal sealing

Why choose Spcera glass to metal seals manufacturer

-Metallic glass adopts quality management system

-Customizable glass-to-metal seals

Frequently Asked Questions (FAQs) for B2B Buyers of glass to metal hermetic seals

-What is the glass to metal seal market?

-What fields can glass-metal seals be used in?

-What quality assurance processes and certifications are crucial when sourcing glass-to-metal seals?

What is a Glass to Metal Seal?

A glass-to-metal seal (GMS) is a critical component used to create a permanent, airtight bond between glass and metal, ensuring a hermetic enclosure that prevents leaks and contamination. This seal is formed by heating glass and metal together until the glass melts and adheres to the metal, forming a strong, durable joint. Glass-to-metal seals are vital in applications where long-term, reliable performance is necessary, especially in extreme conditions such as high temperatures, vacuum environments, and fluctuating pressures.

What is the Definition of a Glass to Metal Sealing?

A glass-to-metal seal (GMS) is a specialized joint that securely bonds glass to metal in a way that maintains high levels of hermeticity (airtightness) and reliability under various environmental conditions. This type of seal plays a crucial role in industries requiring high-performance seals, such as electronics, aerospace, and energy sectors. The seal is achieved by fusing molten glass with a metal to form a hermetic barrier that can withstand extreme temperatures, pressures, and other mechanical stresses.

How Are Glass-to-Metal Seals Made?

The process of making a glass-to-metal seal involves several stages, each of which is critical to ensuring the final product’s durability and functionality. The key steps include:

Selection of Materials: Both the metal and glass must have compatible properties to ensure successful bonding.

Heating: The glass and metal components are heated together to the point where the glass melts and forms a bond with the metal surface.

Cooling: The assembly is then carefully cooled to solidify the glass and maintain its bond with the metal.

Inspection: After cooling, the seals are tested for their integrity, including leak testing, to ensure they meet the necessary specifications for performance.

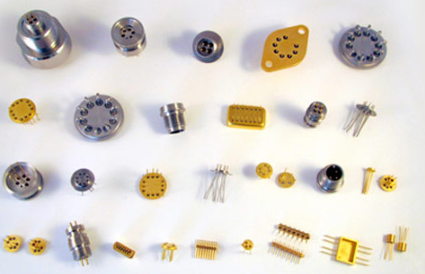

Understanding Glass-to-Metal Seal Types and Applications

Glass-to-metal seals come in various designs, each suited to different applications. Here’s an overview of some common types, their characteristics, and their primary uses:

|

Seal Type |

Features |

B2B Applications |

Advantages |

Disadvantages |

|

Compression Seal |

Provides a tight bond through compressive forces |

Electronics, automotive, aerospace |

High sealing strength |

Requires precise alignment |

|

Flange Seal |

Metal flange and glass components fused together |

Medical devices, sensors, industrial equipment |

Cost-effective, easy to manufacture |

Lower resistance to high temperatures |

|

Bushing Seal |

Uses a glass insert and a surrounding metal body |

Battery sealing, hermetic packaging |

Excellent for high-frequency applications |

Complex manufacturing process |

|

Axial Seal |

Glass and metal are combined in a radial seal around the perimeter |

Military, defense, aerospace |

Robust in harsh environments |

Limited flexibility in design |

|

Radial Seal |

Seals are created around the perimeter in a circular design |

Semiconductor packaging, industrial sensors |

High resistance to environmental stress |

May not be cost-effective for large-volume production |

Common B2B Applications:

1.Aerospace: Used in satellite components, avionics, and space systems to prevent leakage in sensitive electronic devices.

2.Electronics: In devices like LED lighting, glass-to-metal seals are used to ensure airtight enclosures.

3.Medical Devices: Seals are vital for packaging sensitive medical equipment where contamination must be avoided.

4.Energy: Lithium-ion battery seals are an example of critical applications in energy storage systems.

Metal to Glass Seal Material Selection Guide

Choose the Right Metal Material

Selecting the right metal is essential for the performance and durability of glass-to-metal seals. Here are some common metals used:

1.Nickel:

A versatile and widely used material, nickel has excellent thermal expansion properties that match well with glass. It's corrosion-resistant and often used in high-temperature applications.

- Advantages: High strength, good corrosion resistance.

- Disadvantages: Can be expensive.

- Price: Moderate.

2.Kovar:

A high-expansion alloy that is often used when a perfect match with glass thermal expansion is required. Ideal for high-precision applications.

- Advantages: Excellent compatibility with glass.

- Disadvantages: Higher cost.

- Price: High.

3.Stainless Steel:

Known for its robustness and resistance to corrosion, stainless steel is commonly used for applications in harsh environments.

- Advantages: Durable, cost-effective.

- Disadvantages: May not offer the best thermal expansion match for some glasses.

- Price: Low to moderate.

(h3)What Is the Most Common Material in Glass?

The most commonly used glass materials in glass-to-metal seals are lead-free glass and borosilicate glass due to their superior mechanical properties and ability to form strong, reliable bonds with metals.

1.Lead-Free Glass:

This material is favored for its environmentally friendly nature and excellent sealing properties.

- Advantages: Non-toxic, strong bond with metal.

- Disadvantages: Higher processing cost.

- Price: Moderate.

2.Borosilicate Glass:

Known for its low thermal expansion and high resistance to thermal shock, borosilicate glass is ideal for high-precision applications.

- Advantages: High thermal resistance, durable.

- Disadvantages: Can be brittle.

- Price: Moderate.

(h3)The Combination of Glass and Metal

The combination of metal and glass is critical for creating a hermetic seal. The properties of the glass must complement those of the metal to achieve a lasting bond. A mismatch in the thermal expansion coefficients between the materials can lead to stress and eventual failure of the seal.

Comprehensive Cost and Pricing Analysis for Glass-to-Metal Seals Procurement

When considering procurement of glass-to-metal seals, cost is one of the most critical factors. The price of these seals is influenced by several variables:

- Material Choice: Premium materials like Kovar or nickel-based alloys are more expensive than stainless steel.

- Manufacturing Complexity: Custom seals or seals for high-precision applications often come at a higher cost.

- Volume: Large-scale production can lower unit costs, whereas small batches increase per-unit pricing.

- Testing and Quality Assurance: High-quality assurance processes and rigorous testing add to the overall cost but are essential for ensuring the seals perform as required.

On average, the cost of glass-to-metal seals can range from a few dollars per unit for standard seals to several hundred dollars for custom-designed, high-performance seals.

Advantages of Glass-to-Metal Sealing

Hermetic Sealing: Glass-to-metal seals are known for their ability to provide a hermetic seal, which is crucial in preventing leakage of gases or liquids.

1.Thermal Resistance:

These seals can withstand extreme temperature variations, making them ideal for use in high-temperature environments.

2.Electrical Insulation:

Glass-to-metal seals provide excellent electrical insulation, making them perfect for electronic and electrical applications.

3.Durability:

With proper manufacturing and material selection, glass-to-metal seals can last for years, even in harsh environments.

Why Choose SPCERA Glass-to-Metal Seals Manufacturer

SPCERA is a leading manufacturer of glass-to-metal seals that adheres to the highest standards of quality and reliability. Here’s why you should consider SPCERA for your glass-to-metal sealing needs:

Metallic Glass Adopts Quality Management System

SPCERA employs a comprehensive quality management system to ensure the highest standards of product quality. With certifications such as ISO9001, ISO14001, and GJB9001C, SPCERA is committed to maintaining environmental sustainability while delivering top-tier products.

Customizable Glass-to-Metal Seals

SPCERA’s glass-to-metal seals are highly customizable to meet specific customer needs. For example, their lithium battery caps are engineered to meet strict leakage criteria (≤1x10⁻⁹ Pa*m³/s) and high insulation resistance (500 MΩ at 500V DC). The company ensures a 99.7% yield rate in production, ensuring high-quality seals for critical applications.

|

Feature |

Specification |

|

Leakage Rate |

≤ 1x10⁻⁹ Pa*m³/s |

|

Insulation Resistance |

≥ 500 MΩ (500V DC) |

|

Pulling Force |

2000, 2100, 2200 Newton |

|

Weldable Nickel Pin |

Yes |

Frequently Asked Questions (FAQs) for B2B Buyers of Glass-to-Metal Hermetic Seals

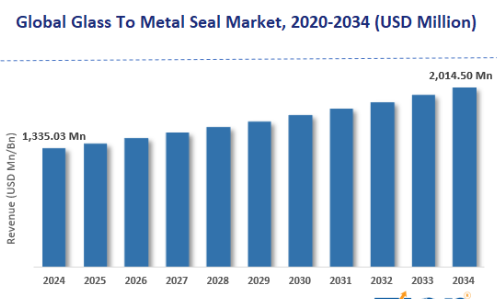

What is the Glass-to-Metal Seal Market?

The glass-to-metal seal market is a highly specialized segment within the materials science and manufacturing industries. It caters to sectors like aerospace, electronics, medical devices, and energy storage, where hermetic sealing is critical.

What Fields Can Glass-Metal Seals Be Used In?

Glass-to-metal seals are used in a wide variety of fields, including:

Aerospace and satellite technology

Electronics (e.g., LED packaging)

Medical devices (e.g., implantable devices)

Energy storage (e.g., lithium-ion battery sealing)

What Quality Assurance Processes and Certifications Are Crucial When Sourcing Glass-to-Metal Seals?

When sourcing glass-to-metal seals, it’s essential to look for suppliers with stringent quality assurance processes. Certifications such as ISO9001, ISO14001, and specific industry certifications (e.g., GJB9001C) are crucial in ensuring product reliability and compliance with environmental standards.

By understanding these elements of glass-to-metal seals, you can make more informed purchasing decisions that align with your specific business needs and applications. Whether you’re sourcing for electronics, aerospace, or other high-performance sectors, selecting the right seal is essential for ensuring product durability and efficiency.