what are technical ceramics?

Release time:2025-09-15

Technical ceramics, also known as advanced or engineering ceramics, are materials made from inorganic, non-metallic compounds that undergo high-temperature processing. These materials are designed for specific, high-performance applications in various industries such as aerospace, electronics, automotive, and medical devices. Unlike traditional ceramics, which are often used for artistic purposes or household items, technical ceramics are engineered to offer superior properties such as strength, wear resistance, electrical insulation, and thermal stability. In this article, we will delve into the composition, manufacturing processes, advantages, and applications of technical ceramics, with a special focus on Spcera technical ceramics.

What is steatite ceramic material composed of?

-Technical Ceramic Manufacturing Methods & Processes

-Five different types of technical ceramic materials

Ceramics vs Metals, Polymers & Refractories

What are the advantages of technical ceramics?

-Advanced technical ceramics increase sensor life

-Technical ceramics are chemically stable

What are the application scenarios of Superior technical ceramics?

-Steatite ceramic beads improve the pressure resistance of terminals

-Oxygen sensor sealing powder ring resists harsh environment

Top technical ceramics manufacturers

FAQ

-What is the lifespan of an O2 sensor?

-What is sealant powder?

-What is the difference between technical and non technical ceramics?

What is Steatite Ceramic Material Composed Of?

One of the most common types of technical ceramics is steatite ceramic. Steatite, also known as soapstone, is a naturally occurring mineral composed primarily of talc, with traces of chlorite and pyroxenes. This ceramic material has a unique combination of properties, making it highly valued in electronic applications, especially for components that require excellent electrical insulating properties.

Key Components of Steatite Ceramic:

1.Talc (Magnesium silicate): Provides excellent thermal stability and electrical insulating properties.

2.Alumina (Al2O3): Adds strength and hardness to the ceramic material.

3.Silica (SiO2): Contributes to its resistance to thermal shock and high temperatures.

4.Calcium Oxide (CaO): Improves the mechanical properties of the ceramic.

Steatite ceramics are widely used in the production of components such as electrical insulators, resistors, capacitors, and other electrical equipment. Their affordability and versatility make them a popular choice in industries requiring insulation and mechanical protection.

Technical Ceramic Manufacturing Methods & Processes

The production of technical ceramics involves a series of carefully controlled processes that transform raw materials into high-performance materials. The key stages of manufacturing technical ceramics are as follows:

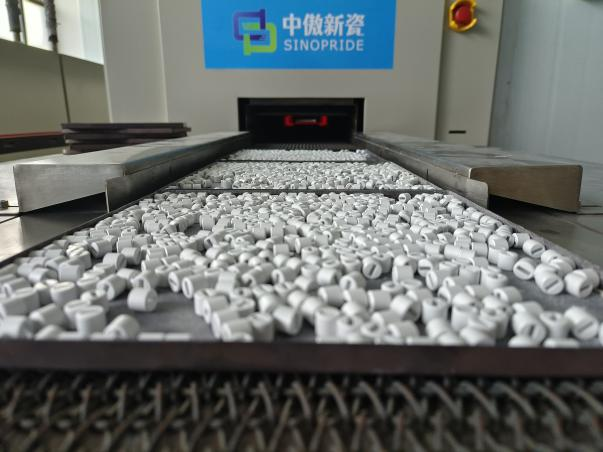

Powder Processing: Raw materials such as clay, alumina, and other compounds are crushed into fine powders. The powders are mixed with binders, plasticizers, and additives to create a paste-like consistency.

Shaping: After the materials are prepared, they are shaped into desired forms using various techniques such as pressing, extrusion, and injection molding. This shaping process allows the creation of complex geometric shapes required for specific applications.

Sintering: The shaped materials are then heated in a furnace (kiln) to a high temperature, a process known as sintering. This process removes any remaining moisture or volatile substances and densifies the ceramic material, significantly improving its strength and durability.

Finishing: After sintering, the ceramic parts are often ground, polished, or coated to meet specific performance requirements. For example, the ceramic components may undergo surface treatments to improve their resistance to wear, corrosion, or temperature extremes.

Five Different Types of Technical Ceramic Materials

There are many types of technical ceramics, each with distinct properties suited for particular applications. Below are five commonly used types of technical ceramics:

Steatite Ceramics:

Properties: Excellent electrical insulation, thermal stability, and cost-effectiveness.

Applications: Electrical components like resistors, capacitors, and insulators.

Alumina Ceramics (Al2O3):

Properties: Hardness, high wear resistance, and high thermal conductivity.

Applications: Cutting tools, medical implants, and high-temperature industrial applications.

Silicon Nitride (Si3N4):

Properties: High strength, thermal shock resistance, and wear resistance.

Applications: Bearings, automotive engine components, and turbine blades.

Zirconia Ceramics (ZrO2):

Properties: High strength, toughness, and resistance to cracking.

Applications: Dental implants, oxygen sensors, and high-performance engineering components.

Titanium Diboride (TiB2):

Properties: High hardness and electrical conductivity.

Applications: Cutting tools, armor, and electronics components.

These ceramics are engineered to perform under extreme conditions, making them essential in industries that demand high reliability, such as aerospace, medical, and automotive industries.

Ceramics vs Metals, Polymers & Refractories

When comparing technical ceramics to metals, polymers, and refractories, the primary distinction lies in the properties that make each material ideal for specific applications.

1.Ceramics vs Metals:

Strength: Ceramics generally exhibit higher compressive strength, while metals are more flexible and can endure bending.

Thermal Resistance: Ceramics can withstand higher temperatures without degrading, unlike metals that may melt or deform at elevated temperatures.

Electrical Insulation: Technical ceramics are excellent insulators, unlike metals, which are typically conductive.

2.Ceramics vs Polymers:

Flexibility: Polymers are more flexible and lightweight, but they tend to degrade at higher temperatures, whereas ceramics offer superior strength and thermal stability.

Durability: Ceramics are highly durable and resistant to wear, while polymers are more susceptible to abrasion and environmental degradation.

3.Ceramics vs Refractories:

Refractories are a subset of ceramics specifically designed to withstand high temperatures. They are used in applications such as furnaces and kilns. All refractories are ceramics, but not all ceramics are refractories.

What Are the Advantages of Technical Ceramics?

The unique properties of technical ceramics offer several advantages over traditional materials, making them highly desirable for specialized applications.

Advanced technical ceramics increase sensor life

In demanding environments, sensors are exposed to extreme conditions like high temperatures, pressure, and corrosive elements. Technical ceramics, such as zirconia and alumina, provide excellent protection against these harsh conditions, thus extending the lifespan of sensors and other electronic components.

Technical Ceramics Are Chemically Stable

Technical ceramics are highly resistant to chemical corrosion. Unlike metals and polymers, which may degrade over time, ceramics do not react with most acids, bases, or other chemicals. This stability makes them ideal for use in the chemical, medical, and energy industries.

What Are the Application Scenarios of Superior Technical Ceramics?

The versatility of technical ceramics makes them suitable for a wide range of applications across various industries.

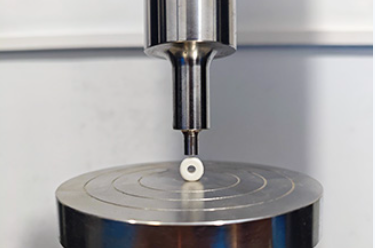

Steatite Ceramic Beads Improve the Pressure Resistance of Terminals

Steatite ceramic beads are used in electronic terminals to enhance their pressure resistance and improve overall reliability. These beads can withstand high mechanical stress, ensuring that the electrical connection remains stable and durable.

Oxygen Sensor Sealing Powder Ring Resists Harsh Environments

Oxygen sensors used in automotive and industrial applications need to operate in extremely hot and chemically aggressive environments. Sealing powder rings made from zirconia or alumina ceramics provide a robust seal, protecting the sensor from the elements and enhancing its lifespan.

Top Technical Ceramics Manufacturers

Some of the top manufacturers of technical ceramics are known for producing high-quality, durable materials for a range of industries:

1.CoorsTek: Specializes in providing advanced ceramic materials for aerospace, automotive, and electronics applications.

2.CeramTec: Known for offering a broad range of technical ceramic products used in medical, industrial, and automotive sectors.

3.Spcera Technical Ceramics: A prominent manufacturer that focuses on creating advanced technical ceramics designed for high-performance applications. Spcera is known for its innovative solutions in industries such as electronics, automotive, and energy.

4.Kyocera Corporation: A leader in the ceramic industry, producing both consumer and industrial ceramics.

FAQ

What is the lifespan of an O2 sensor?

The lifespan of an O2 sensor varies, but typically it lasts between 50,000 to 100,000 miles (80,000 to 160,000 kilometers). The durability of the sensor is greatly enhanced by the use of high-quality ceramic materials like zirconia.

What is Sealant Powder?

Sealant powder is used to create seals in sensitive components, such as oxygen sensors, to prevent leaks and protect against contaminants. It is often made from alumina or zirconia, offering resistance to high temperatures and chemicals.

What is the Difference Between Technical and Non-Technical Ceramics?

Technical ceramics are engineered for specific applications that require high strength, wear resistance, thermal stability, and electrical insulation. Non-technical ceramics, on the other hand, are primarily used for decorative or everyday items like pottery, tiles, and glassware.

Conclusion

Technical ceramics are integral materials in industries that require high-performance solutions. With their superior properties—such as chemical stability, high strength, and excellent thermal resistance—technical ceramics play a crucial role in applications ranging from electrical components to aerospace technology. Leading manufacturers like Spcera Technical Ceramics continue to innovate and provide tailored solutions for industries worldwide. Whether for improving sensor life or enhancing component durability, technical ceramics are indispensable in modern technology.