How Hermetic Feedthroughs Ensure the Reliability of Sealed Systems

Release time:2025-08-30

In various harsh environments, the reliability of sealed systems is crucial, especially in applications that require electrical connections. Hermetic feedthroughs, as key components ensuring the stable operation of sealed systems, provide reliable transmission of electrical and signal connections while preventing external contaminants (such as water, dust, and gases) from entering the sealed system. This article will delve into the working principles, types, evaluation methods, and applications of hermetic feedthroughs, explaining how high-quality hermetic feedthroughs can ensure the long-term reliability of systems.

What Are hermetically sealed feedthrough?

-How Hermetic Feedthroughs Work

-Construction of hermetic feed thru

-Why Hermetic Seals Are Crucial

-Custom Hermetic Feedthroughs

-Glass-to-Metal Feedthroughs

-Ceramic-to-Metal Feedthroughs

-hermetically sealed electrical feedthrough

Evaluating hermetic feedthrough connectors Performance

-hermetic seal testing of Glass Seal

-Hermetic Seal Assessment Type

Applications of Hermetic Feedthroughs

SINOPRIDE:Your trusted GTMS Feedthrough manufacturer

What Are Hermetic Feedthroughs?

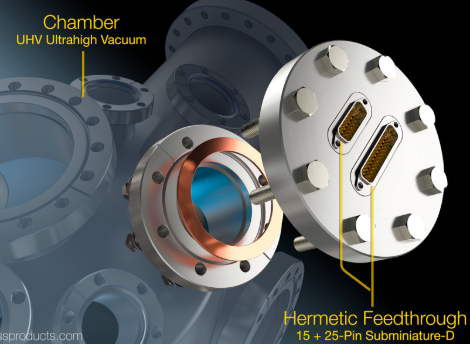

Hermetic feedthroughs are specialized components designed to provide reliable electrical or optical signal transmission through a sealed barrier, such as a pressure vessel or vacuum chamber, while maintaining a hermetically sealed environment. These feedthroughs ensure that no gases, liquids, or contaminants can pass through the barrier, protecting sensitive internal components from external conditions like moisture, dust, and corrosive agents. Commonly used in industries such as aerospace, medical devices, electronics, and energy, hermetic feedthroughs come in various materials, including metal, ceramic, and glass, to meet the demands of extreme environments such as high pressure, high temperature, or vacuum conditions.

How Hermetic Feedthroughs Work

Hermetic feedthroughs are components designed to transmit electrical or optical signals from a sealed area to the external environment. They are designed to provide stable electrical or signal connections while maintaining air-tight and liquid-tight seals. Whether in aerospace, medical, automotive, or industrial applications, hermetic feedthroughs ensure safe contact between internal circuits or systems and the outside world.

These feedthroughs are typically made from materials such as metal, ceramics, and glass. Their sealing design prevents air, gases, water, or other contaminants from entering the sealed system, ensuring system reliability even in extreme working environments like high temperatures, high pressures, or vacuum conditions.

Construction of Hermetic Feedthroughs

The basic structure of a hermetic feedthrough typically consists of three main components: the internal conductive part (for transmitting signals or power), the external sealing part (to prevent the ingress of external materials), and the connection interface (ensuring seamless integration of the feedthrough with the system). These structures enable the hermetic feedthrough to transmit electrical signals with the outside world while maintaining the integrity of the sealed system without affecting the internal components.

Why Hermetic Feedthroughs Are Crucial

The role of hermetic feedthroughs is not limited to electrical connections; they are also essential in protecting sealed systems from external contaminants. In industries with extremely stringent environmental requirements, such as aerospace, military, and medical equipment, any external intrusion can lead to system failures or catastrophic consequences. Therefore, ensuring the integrity and stability of these systems makes hermetic feedthroughs an important component in ensuring system reliability.

Types of Hermetic Feedthroughs

Custom Hermetic Feedthroughs

For certain specialized applications, standard hermetic feedthroughs may not meet the requirements. In such cases, custom hermetic feedthroughs come into play. These feedthroughs are tailored to meet the unique demands of specific systems, offering more flexibility in terms of materials, shapes, and functionality. Custom feedthroughs are widely used in aerospace, military equipment, and high-end research devices, where they need to perform in extreme working conditions.

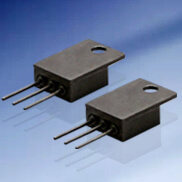

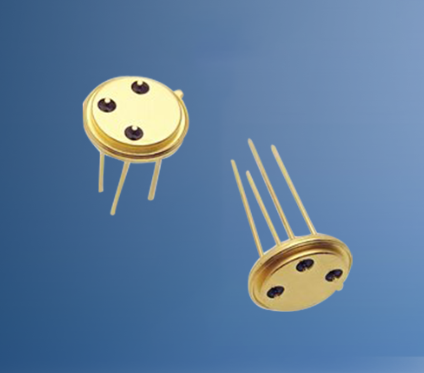

Glass-to-Metal Feedthroughs

Glass-to-metal feedthroughs are a common type of hermetic feedthrough that combines the sealing properties of glass with the strength and conductivity of metal. These feedthroughs are typically used in high-pressure, high-temperature environments and are known for their corrosion resistance and high strength. They are widely applied in aerospace, nuclear power, and other industries.

Ceramic-to-Metal Feedthroughs

Ceramic-to-metal feedthroughs are typically used in applications requiring high insulation, such as high-frequency electrical devices and high-voltage systems. Ceramic materials provide excellent insulation properties, while the metal component ensures strength and reliable electrical connections. These feedthroughs are particularly useful in power equipment, electronic systems, and communication fields.

Electrically Sealed Feedthroughs

Electrically sealed feedthroughs are primarily designed to ensure safe transmission of electrical signals in a sealed environment. These feedthroughs not only need to maintain the integrity of the sealed system but also need to have good electrical conductivity. They are widely used in medical devices, automotive electronics, and data communication devices, ensuring system stability in high-humidity, high-temperature, or high-pressure conditions.

Evaluating Hermetic Feedthrough Connector Performance

hermetic seal testing of Glass Seal

The key to evaluating the performance of glass-sealed feedthroughs is ensuring they have extremely low leak rates. This is typically done through leak testing, with common methods including helium leak testing and pressure pulse testing. These tests ensure that the glass-sealed feedthrough can effectively prevent any gas or liquid leakage during practical applications.

Hermetic Seal Assessment Methods

In addition to leak testing, hermetic feedthroughs need to undergo high-temperature, high-humidity, and corrosion testing. These tests simulate the feedthrough’s performance in real-world operating conditions to ensure that it does not experience leaks or performance degradation over time. Common assessment methods include pressure cycle testing, temperature cycle testing, and electrical performance testing.

Applications of Hermetic Feedthroughs

Hermetic feedthroughs have a wide range of applications across various industries, where they play a vital role in ensuring the stability and reliability of systems. Below are some specific industries and application examples:

- Aerospace and Satellites

In aerospace and satellite fields, hermetic feedthroughs are used in high-pressure, high-temperature, and vacuum environments to ensure reliable transmission of electrical signals and system sealing. Hermetic feedthroughs prevent external contaminants from entering satellites or spacecraft, ensuring long-term stable operation of the equipment.

- Medical Devices

Implantable medical devices (such as pacemakers and cochlear implants) rely on hermetic feedthroughs to ensure the transmission of electrical signals while protecting the devices from the moist environment inside the body. The stability of hermetic feedthroughs is crucial in these applications.

- Air Conditioning and Compressors

In air conditioning compressors and cooling systems, hermetic feedthroughs are used to provide electrical connections and ensure the stability of systems in high-temperature and high-humidity conditions. These feedthroughs prevent external air, moisture, or dust from entering the compressor, maintaining long-term efficiency.

- Power and High-Voltage Equipment

In substations, nuclear power plants, and other high-voltage power equipment, hermetic feedthroughs provide highly reliable electrical connections, preventing external environmental factors from affecting the equipment. They ensure safe operation of the system under extreme voltage and climatic conditions.

- Automotive and Electric Vehicles (EV)

In electric vehicles and hybrid cars, hermetic feedthroughs are used to ensure the electrical connections of battery management systems, charging ports, and other components are protected from external environmental factors, thereby ensuring long-term vehicle reliability.

SINOPRIDE: Your Trusted GTMS Feedthrough Manufacturer

SINOPRIDE is dedicated to providing high-quality GTMS (Glass-to-Metal Sealed) feedthroughs to clients worldwide, ensuring system stability in various extreme environments. As an industry-leading manufacturer, we ensure that each product meets international standards through advanced technology and stringent quality control, offering reliable solutions to our customers.