Technological breakthrough of glass powder: Wide application of low-temperature glass powder

Release time:2025-08-25

As global industrial technology continues to evolve and environmental awareness increases, glass powder has emerged as a key industrial material with unique physical and chemical properties. It is widely used in various fields due to its versatility and technological breakthroughs. Glass powder's role in both high-end manufacturing and modern green production makes it an essential material across many industries. This article explores the technological innovations in glass powder, focusing on the application of low-temperature glass powder and breakthroughs in its recycling technology. It also examines how these innovations contribute to energy conservation, emission reduction, and a circular economy, and finally highlights the advantages of SINOPRIDE glass powder and glass-metal seals.

What is Glass Powder?

Glass powder is a fine particulate material produced by crushing and grinding glass raw materials. Known for its excellent stability, high-temperature resistance, and exceptional surface treatment properties, glass powder is widely used in coatings, ceramics, glass-metal seals, and other high-end applications. Its fine particulate structure not only improves surface finishes but also provides excellent corrosion resistance and mechanical strength, making it a critical material in various industrial applications.

With ongoing advancements in technology, the particle size, chemical composition, and range of applications for glass powder have greatly expanded. Today, it plays a crucial role in traditional glass products and is also extensively used in modern electronics, medical devices, and aerospace applications.

Technological Breakthroughs in Glass Powder: Low-Temperature Glass Powder

Low-temperature glass powder is one of the most significant technological advancements in the glass powder industry. Traditional glass powders require high temperatures for melting and binding processes, consuming substantial energy and creating negative environmental impacts. Low-temperature glass powder, however, optimizes its composition and manufacturing process to achieve the same results at lower temperatures, thereby reducing energy consumption and minimizing the adverse effects of high temperatures on other materials.

This breakthrough improves process efficiency and expands the range of applications for glass powder, particularly in products and materials that are sensitive to high temperatures. For many precision-driven applications, low-temperature glass powder enables better control over the manufacturing process, avoiding damage to sensitive equipment and materials.

Applications of Low-Temperature Glass Powder

Glass-Metal Seals

Glass-metal seals (GMS) are composite materials made by combining glass powder with metal. They are widely used in aerospace, electronics, and medical device industries. Glass powder melts and bonds with metal, forming a sealing layer that offers excellent high-temperature resistance, sealing capabilities, and corrosion resistance. The use of low-temperature glass powder allows for the manufacturing of these seals at lower temperatures, reducing damage to precision equipment and materials, especially for electronic component packaging.

Applications: Aerospace shell seals, electronic component packaging, high-temperature sealing for medical devices, etc.

Technical Requirements: High heat resistance, excellent sealing performance, corrosion resistance, and mechanical strength.

Specific Parameters: Melting point below 500°C, suitable for use at room to moderate temperature ranges.

Features: Low-temperature fusion, energy-efficient, and enhanced material stability.

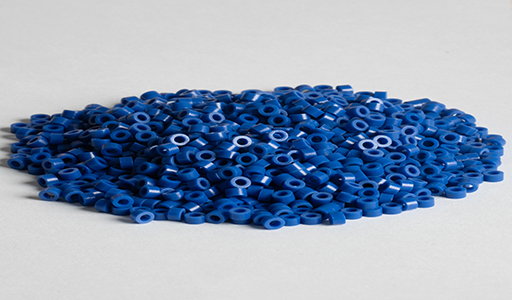

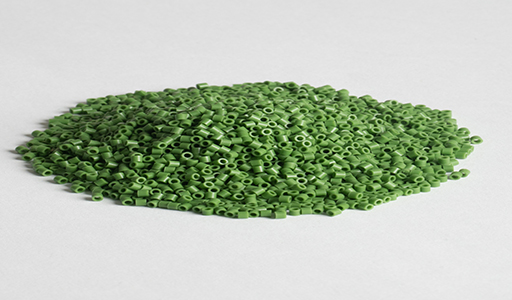

Glass Preforms

Glass preforms are semi-finished products created by forming glass powder into specific shapes and sizes. These preforms serve as the foundation for producing complex-shaped glass components or glass-metal seals. The use of low-temperature glass powder makes the preform manufacturing process more efficient, reducing reliance on molds and heat sources, and improving production flexibility.

Applications: Optical fiber connectors, optical components, electronic packaging, etc.

Technical Requirements: High precision, stable shapes, and defect-free performance.

Specific Parameters: Good flowability, uniformity, and thermal resistance.

Kovar Glass Seals

Kovar glass sealing technology is a classic example of glass powder used in high-end industrial applications. Kovar is a metal alloy with a unique composition that matches the thermal expansion coefficient of glass, allowing for stress-free fusion between the two. Low-temperature glass powder further enhances the fusion process, reducing energy consumption during manufacturing.

Applications: Sensors, circuit packaging, and high-precision electronic components.

Technical Requirements: Strong compatibility, high heat resistance, and high stability.

Specific Parameters: Moderate melting point with excellent thermal expansion matching.

Sustainable Development of Glass Powder

With increasingly stringent global environmental standards, sustainability in glass powder production is becoming a focal point across industries. Through process optimization, glass powder manufacturing not only enables waste recycling but also reduces the negative environmental impact through green production practices. Sustainable glass powder manufacturing not only meets environmental regulations but also supports corporate social responsibility initiatives.

Glass Powder Recycling Breakthroughs

Recycling technology for glass powder is a vital aspect of its sustainable development. Advanced recycling techniques allow waste glass materials to be transformed into high-quality glass powder, significantly reducing resource waste and lowering carbon footprints. Recycled glass powder helps save raw materials and reduces environmental pollution caused by waste products.

Recycling Process: Advanced separation, cleaning, and grinding technologies are used to extract usable powder from discarded glass, ensuring high purity and quality.

Environmental Impact: Substantially reduces energy consumption and greenhouse gas emissions during manufacturing.

ESG Value: By recycling and reusing materials, businesses improve their environmental, social, and governance (ESG) performance, aligning with sustainability goals.

What is Recycled Glass Powder Used For?

Recycled glass powder can be used in traditional glass product manufacturing and has broader applications, such as in glass-metal seals, ceramic coatings, and construction materials. By recycling glass powder, companies can reduce raw material consumption, lower production costs, and minimize environmental pollution.

Application Areas: Electronic packaging, construction fillers, ceramic coatings, etc.

Environmental Benefits: Reduces reliance on new resources and lowers carbon emissions during production.

Future Application Trends of Glass Powder

With the continuous advancement of industrial technology and the growing demand for environmental protection, the application scope of glass powder will become broader, and market demand will continue to rise. In the future, glass powder will not only continue to play an important role in traditional glass products but will also find more widespread applications in high-end fields such as new energy, environmental protection technologies, and smart manufacturing.

Market Trend:

With the introduction of green environmental policies, the demand for recycled glass powder and low-temperature glass powder will gradually increase. In the future, glass powder will be more widely used in high-tech fields such as solar photovoltaics, smart device packaging, and more.

Product Trend:

As technological innovations continue, the performance of glass powder will be further optimized, and production processes will become more energy-efficient, driving the broader application of glass powder in environmental protection and high-end manufacturing.

Glass powder's innovative applications, particularly the breakthroughs in low-temperature glass powder and glass-metal seals, have revolutionized various industries. SINOPRIDE glass powder products, with their high-quality low-temperature glass powder and advanced recycling technologies, provide not only superior product performance but also sustainable development solutions for businesses. Whether in the precision manufacturing of glass-metal seals or in promoting environmental sustainability, SINOPRIDE offers comprehensive technical support and product guarantees, helping businesses thrive in an increasingly competitive market.

In conclusion, glass powder has become an essential material driving innovation in various industries, and SINOPRIDE stands as a leading provider of glass powder solutions, committed to environmental sustainability and technological advancement.