Borofloat Glass in the Glass to Metal Sealing Process

Release time:2025-11-11

Glass-to-metal sealing is a crucial process used to bond glass and metal components to create airtight, watertight, and durable seals. It is vital in high-tech industries such as electronics, aerospace, medical devices, and telecommunications. Borofloat glass, a type of borosilicate glass, plays a key role in this process due to its low thermal expansion, high chemical resistance, and excellent thermal stability.

Introduction to Glass to Metal Sealing

-Definition and importance of glass-to-metal seals

-Overview of glass metal sealing technology

What is borofloat glass?

-What are the properties of borosilicate glass?

-What's the difference between regular glass and borosilicate glass?

Understanding the glass metal sealing process

-How are glass to metal seals made?

-What is the difference between hermetic and non-hermetic?

The role of borofloat glass in achieving a reliable hermetic seal

-How borofloat glass enhances sealing integrity

-Its thermal expansion properties and compatibility with metals

-Contribution to long-term durability and reliability of seals

What are the advantages of borosilicate glass?

SPCERA Glass metal seal manufacturers:Supply of specialty glass

Introduction to Glass to Metal Sealing

Definition and Importance of Glass-to-Metal Seals

Glass-to-metal sealing is a specialized process used to bond glass and metal components in a way that creates an airtight, watertight, and durable seal. This method is vital in many high-tech applications, including electronics, aerospace, medical devices, and telecommunications. The primary goal of glass-to-metal sealing is to ensure that the bond between glass and metal can withstand harsh environmental conditions, including temperature variations, mechanical stress, and exposure to corrosive elements, all while maintaining its hermetic integrity.

Overview of Glass-Metal Sealing Technology

Glass-to-metal seals are created by heating a glass material to its softening point and then applying it to a metal surface, where it bonds upon cooling. This process is particularly valuable in creating components like vacuum tubes, sensors, and electrical feedthroughs. The sealing materials used must have properties that allow them to effectively bond with metal, while also being able to resist thermal cycling and mechanical forces over time. The development of advanced glasses, such as Borofloat glass, has revolutionized the sealing process, offering better performance in demanding applications.

What is Borofloat Glass?

What Are the Properties of Borosilicate Glass?

Borosilicate glass is a type of glass composed primarily of silica and boron oxide. Its unique chemical composition provides several key benefits:

1.Low thermal expansion: Borosilicate glass has a low coefficient of thermal expansion (CTE), which means it doesn't expand or contract as much as regular glass when subjected to temperature changes. This property makes it ideal for applications involving extreme temperature fluctuations.

2.High thermal stability: Borosilicate glass can withstand high temperatures (typically up to around 500°C or 932°F) without cracking or deforming. This makes it suitable for environments where heat resistance is critical.

3.Chemical resistance: Borosilicate glass resists most chemicals, including acids, making it ideal for laboratory settings or environments where the material will be exposed to corrosive substances.

4.Transparency: It also has excellent optical clarity, which is important for applications in scientific instrumentation, optics, and other precision industries.

What's the Difference Between Regular Glass and Borosilicate Glass?

The primary difference between regular glass (e.g., soda-lime glass) and borosilicate glass lies in their chemical composition and thermal properties. Regular glass, which is made from a combination of silica and soda-lime, tends to have a higher thermal expansion rate and lower thermal shock resistance compared to borosilicate glass. Borosilicate glass, because of its inclusion of boron oxide, exhibits much better performance when exposed to temperature extremes and is far more durable in these conditions. This makes it the preferred material in high-performance sealing applications, including glass-to-metal seals.

Understanding the Glass-Metal Sealing Process

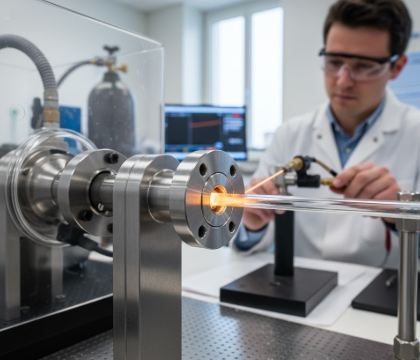

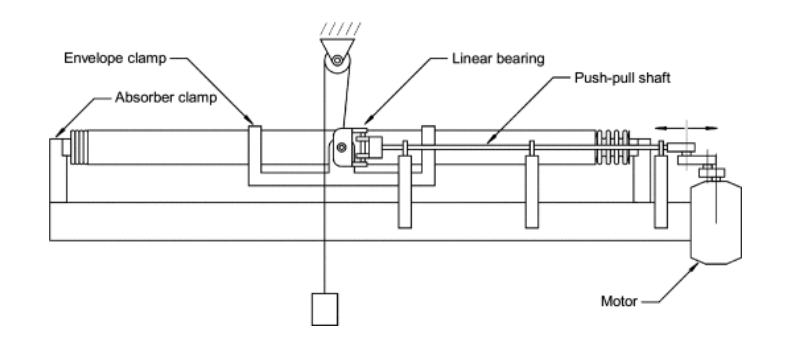

How Are Glass-to-Metal Seals Made?

The process of creating glass-to-metal seals involves several steps, typically starting with the preparation of both the glass and the metal components:

1.Glass Preparation: The glass is heated to its softening point, where it becomes malleable. At this point, the glass can be shaped to fit the metal part it will bond with.

2.Metal Preparation: The metal is also heated and sometimes treated to ensure that it has the proper surface texture for bonding with the glass.

3.Joining: The molten glass is applied to the metal surface and, as it cools, the bond between the glass and metal forms. This bond is created by the expansion of the metal as it heats up and the contraction of the glass as it cools.

4.Sealing: The seal is then thermally treated to ensure complete bonding and to relieve any stresses that may have formed during the cooling process.

The challenge in this process is ensuring that the glass and metal have compatible thermal expansion rates. If these rates are too dissimilar, the bond will fail under stress from temperature fluctuations. This is where specialized glasses, like Borofloat glass, play a critical role.

What Is the Difference Between Hermetic and Non-Hermetic Seals?

1.Hermetic Seals: These seals are airtight and impervious to gases and liquids, making them ideal for high-stakes applications like vacuum environments, medical implants, and electronics. A hermetic seal is essential when maintaining a clean, controlled environment is necessary to ensure the longevity and reliability of the components.

2.Non-Hermetic Seals: These seals are typically used in less demanding applications where the primary requirement is a physical bond rather than an airtight or watertight seal. Non-hermetic seals may allow some degree of gas or moisture penetration, but they still provide mechanical strength and electrical insulation.

The use of Borofloat glass ensures that hermetic seals remain intact under challenging conditions, including extreme temperatures and environmental factors. Its low thermal expansion and excellent bonding properties make it an ideal choice for hermetically sealed components.

The Role of Borofloat Glass in Achieving a Reliable Hermetic Seal

How Borofloat Glass Enhances Sealing Integrity

The unique properties of Borofloat glass make it an excellent choice for ensuring the integrity of glass-to-metal seals, particularly in applications where long-term reliability is crucial. Borofloat glass offers superior thermal expansion characteristics that align well with a variety of metals commonly used in sealing applications, such as stainless steel or Kovar. This compatibility ensures that, even under extreme temperature changes, the bond between the glass and metal remains strong and intact.

In addition to its thermal expansion properties, Borofloat glass has high chemical resistance, which allows it to withstand corrosive environments without degradation. This is especially important in sensitive applications, such as those in the aerospace, medical, and telecommunications industries, where the sealing material must be able to resist chemical exposure over time.

Its Thermal Expansion Properties and Compatibility with Metals

One of the most critical factors in the success of a glass-to-metal seal is ensuring that the glass and metal expand and contract at similar rates when exposed to temperature changes. Borofloat glass, with its low CTE, helps minimize the stress at the interface between glass and metal, which can otherwise lead to seal failure. This property makes Borofloat glass an excellent choice for ensuring the durability and reliability of hermetic seals, particularly in high-temperature or fluctuating temperature conditions.

Contribution to Long-Term Durability and Reliability of Seals

The durability of a hermetic seal depends not only on the initial bonding process but also on its ability to withstand prolonged exposure to thermal cycling, mechanical stress, and environmental factors. Borofloat glass provides a stable, long-lasting solution that ensures the hermetic seal remains intact for the lifetime of the product. Its resistance to thermal shock, combined with its low expansion rate, helps prevent cracking or delamination of the seal during use, even in extreme conditions.

What Are the Advantages of Borosilicate Glass?

There are several advantages to using Borofloat glass in glass-to-metal sealing applications:

1.Superior Thermal Performance: Borofloat glass has a low coefficient of thermal expansion, which ensures that it can handle temperature fluctuations without compromising the seal.

2.Chemical Resistance: Borofloat glass is resistant to most acids and corrosive substances, making it ideal for applications that require protection from chemical degradation.

3.High Durability: The material’s excellent resistance to thermal shock and mechanical stress ensures that seals remain intact over long periods, even in challenging environments.

4.Versatility: Borofloat glass can be used in a wide range of sealing applications, from aerospace and medical to consumer electronics, providing a versatile and reliable solution for many industries.

SPCERA Glass-Metal Seal Manufacturers: Supply of Specialty Glass

SPCERA is a well-known manufacturer specializing in the production of glass-to-metal seals. By offering high-quality specialty glass materials, including Borofloat glass, SPCERA ensures that its clients benefit from the best materials for their sealing needs. With decades of experience, SPCERA provides a range of solutions for industries requiring advanced sealing technology, from high-performance aerospace components to sensitive medical devices.

| Product Category | Application areas | Model | Glass System | Density | Operating Temperature | Coefficient of thermal expansion at 300°C (10⁻⁶ /K) | color |

| Special glass | Iron-sealed glass | ST015 | Si2O-B2O3-R2O | 2.57 | 950-980 | 9.9±0.5 | Dark blue |

| ST408 | Si2O-B2O3-R2O | 2.7 | 925-955 | 10.2±0.5 | Dark blue | ||

| SH604 | Si2O-B2O3-R2O | 2.54 | 950-980 | 9.6±0.5 | White | ||

| SN001 | Si2O-B2O3-R2O | 2.45 | 960-980 | 10.3±0.5 | Dark blue | ||

| Kovar Glass | SK016 | Si2O-B2O3-R2O | 2.28 | 960-980 | 5±0.5 | White | |

| Low-temperature glass solder |

LP080 | P2O5-SnO-ZnO | 3.85 | Vacuum 560 | 13.4±0.5 | Blue | |

| LC-1 | Bi2O3-B2O3-ZnO | 6.6 | Vacuum 600 | 11.7±0.5 | Green |

Conclusion

In the glass-to-metal sealing process, Borofloat glass plays a pivotal role in achieving reliable, durable hermetic seals. Its low thermal expansion, excellent thermal stability, and chemical resistance make it an ideal material for sealing applications where long-term performance is essential. Whether used in electronics, aerospace, or medical technology, Borofloat glass ensures that glass-to-metal seals remain intact, even under challenging conditions. As demand for high-performance sealing solutions continues to grow, the role of Borofloat glass in these critical applications will only become more significant.

Recommended reading

1.What is a glass to metal seal?

2.What does hermetically sealed mean?

3.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors