what does hermetically sealed mean?

Release time:2025-08-27

Hermetic sealing is the process of creating a completely enclosed state between two surfaces to prevent leakage of gases, liquids, or solid particles. It is essential in systems that require complete isolation or protection, especially in harsh environments like high pressure, high temperature, and chemical corrosion. Common methods of crafting hermetic seals include welding, hot pressing, and machining, each suited for specific applications. Key types of seals include glass-to-metal seals, oxygen sensor gaskets, steatite ceramic seals, and customized glass-to-metal seals, each designed for particular environments and performance needs.

what is hermetically sealed?

How to Craft a Hermetic Seal?

Specific type of seal

Application of glass metal seals in lithium battery seals

Application of oxygen sensor gasket in automotive nitrogen oxide sensor

Application of Hermetically sealed ceramic lids in sealed compressors

Custom Hermetic Seal

Benefits of using glass to-metal seal

Conclusion

What is Hermetically Sealed?

Hermetic sealing refers to the process of creating a completely enclosed state between two contact surfaces through a particular material or method, preventing the leakage of gases, liquids, or solid particles. This type of sealing is commonly used in systems or devices that require complete isolation or protection, ensuring that the internal environment is not affected by external contaminants or disturbances. It is especially important in environments with high pressure, high temperatures, or chemical corrosion, where maintaining an effective seal is crucial.

The methods and materials used to achieve a hermetic seal are diverse, depending on the application and the required performance characteristics. Whether in everyday household appliances or highly specialized industrial equipment such as aerospace, military, and energy systems, hermetic sealing technology plays an indispensable role. The reliability and longevity of sealing components are critical to the performance, lifespan, and efficiency of the equipment.

How to Craft a Hermetic Seal?

Creating high-quality hermetic seals is not as simple as just joining two surfaces together. It requires precise design and processes to ensure that the seal remains stable and reliable during use. Several factors must be considered during the manufacturing process, such as the selection of sealing materials, the environmental requirements, the design of the sealing structure, and the relevant manufacturing techniques.

Common methods for crafting hermetic seals include:

Welding:

This method is particularly suitable for creating a tight bond between metal and glass. High temperatures are used to fuse materials together, forming a firm and seamless seal. This technique is highly effective in applications that require high-temperature resistance and electrical insulation.

Hot Pressing:

In this method, heat and pressure are applied to deform the sealing material (such as rubber, plastic, etc.), creating a seal between the contact surfaces. This method is commonly used for elastic seals such as O-rings and gaskets.

Machining:

Precision machining techniques are used to ensure that the sealing surfaces are smooth and free from any imperfections that might cause leaks. By employing high-precision processing, manufacturers can achieve the perfect fit and ensure the seal performs effectively.

Each sealing method is suited to specific application scenarios, so it is crucial to consider the working environment when selecting a sealing method. For example, in high-temperature and high-pressure environments, it is important to choose the right sealing materials and techniques to ensure the seal’s effectiveness and durability.

Specific Types of Seals

There are numerous types of sealing components, each with unique characteristics, specifications, and performance parameters. Below are several common types of seals and their key features and applications.

Application of glass metal seals in lithium battery seals

Key Features: Glass-to-metal seals are highly resistant to high temperatures and capable of withstanding extreme pressure. They also offer excellent electrical insulation properties, making them ideal for high-end electronic and electrical devices.

Specifications and Performance: These seals typically exhibit high stability and corrosion resistance, making them effective in harsh environments.

Applications: Glass-to-metal seals are widely used in lithium battery seals, lithium thionyl chloride battery terminals, and other high-performance battery and electronic products. These products require seals that can maintain stability under high temperature, pressure, and corrosive conditions, which glass-to-metal seals provide.

Application of oxygen sensor gasket in automotive nitrogen oxide sensor

Key Features: Oxygen sensor gaskets must be able to withstand high temperatures and harsh environmental conditions while providing a stable seal that prevents gas leakage, ensuring proper sensor function.

Specifications and Performance: These gaskets are made from elastic materials like silicone or polyurethane, offering excellent temperature resistance and chemical corrosion resistance. Their elasticity ensures that they maintain their sealing properties under varying environmental conditions.

Applications: Oxygen sensor gaskets are commonly used in automotive nitrogen oxide sensors, automotive oxygen sensors, and motorcycle oxygen sensors. These sensors are essential in vehicle emission control systems, where accurate detection of exhaust gases is necessary, and high-quality sealing is critical.

Key Features: Steatite ceramic seals are known for their high mechanical strength, high-temperature resistance, and resistance to chemical corrosion, making them suitable for high-temperature and high-pressure environments.

Specifications and Performance: These seals are not only heat-resistant but also possess excellent electrical insulation properties and are highly resistant to chemical corrosion, ensuring stable performance over time.

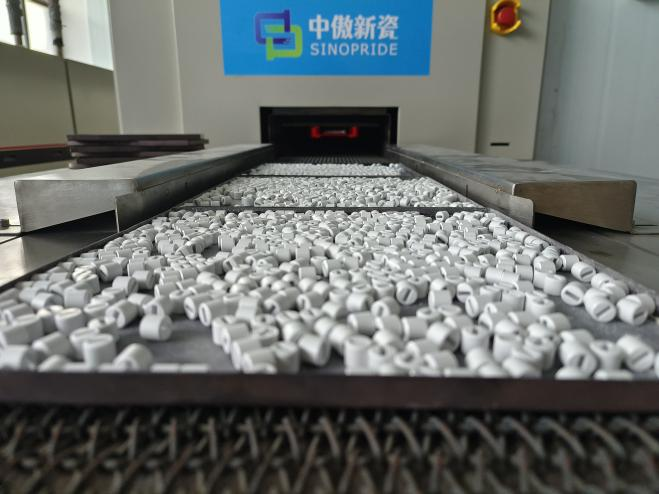

Applications: Steatite ceramic seals are widely used in household appliances like air conditioning compressor terminals, HVAC compressor terminals, and refrigerator compressor terminals. These seals ensure that household appliances operate efficiently and do not experience leaks or other issues during use.

Custom Hermetic Seal

Key Features: Customized glass-to-metal seals are tailored to meet specific application requirements, adapting to different temperature, pressure, and electrical performance needs.

Specifications and Performance: These seals can be customized in size, temperature tolerance, pressure resistance, and other characteristics to meet the strict requirements of particular applications.

Applications: Customized glass-to-metal seals are used in high-end electronic devices, medical instruments, aerospace, and other industries where sealing performance must meet very high standards. These customized seals ensure that devices function efficiently and remain stable under demanding conditions.

Benefits of using glass to-metal seal

Using high-quality sealing components brings several advantages:

Enhanced Equipment Safety: Seals effectively prevent gas leaks, electrical shorts, and other potential hazards, thereby improving the safety of the equipment and reducing the risk of accidents.

Improved Product Reliability: By using high-quality seals, devices can avoid contamination and corrosion, extending their lifespan and increasing their operational stability.

Reduced Maintenance Costs: Equipment with reliable sealing typically requires less frequent maintenance and component replacements, reducing operational and maintenance costs.

Improved Efficiency: In high-temperature, high-pressure, and harsh environments, seals ensure that equipment operates efficiently, minimizing energy loss and improving overall efficiency.

Conclusion

Seals play a vital role in modern industrial and high-tech fields. Whether it is in electronic products, automobiles, home appliances, or advanced medical devices, high-quality seals are crucial for ensuring equipment safety, reliability, and long-term performance. As a leading provider of sealing solutions, SINOPRIDE is dedicated to offering customized, high-performance seals that help industries enhance product performance and ensure stable system operations. With expert technology and superior sealing solutions, SINOPRIDE supports industries in achieving optimal performance and efficiency.

Recommended reading :

1.What are the hermetic solutions-glass to metal seal

2.What does hermetically sealed mean?

3.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors