Choosing Between Unmatched Hermetic Seals and Matched Sealing Solutions

Release time:2025-12-12

Hermetic seals are essential for protecting sensitive components from the external environment. They ensure that no moisture, dust, or gases enter or exit, maintaining the integrity and functionality of the sealed device. When choosing hermetic seals, it's important to understand the differences between unmatched and matched sealing solutions. This blog will explore the key concepts and help you choose the right solution for your specific needs.

https://www.youtube.com/watch?v=dICQtbR5DfY

What qualifies as hermetically sealed?

-How does a hermetic seal work?

-What is the purpose of hermetic seal?

What are the different types of hermetic seals?

-Understanding unmatched hermetic seals

-Exploring matched hermetic seals

-Comparing unmatched hermetic seals vs. matched sealing

A deep dive into glass to metal hermetic seals

-Understanding the key principles in glass to metal seal design

-Exploring the benefits of glass to metal compression seals

SPCERA : Custom hermetic sealing solutions

-When off-the-shelf hermetic seals aren’t enough?

-How glass to metal seals can be custom-tailored?

-Benefits of custom seals for high-performance industries

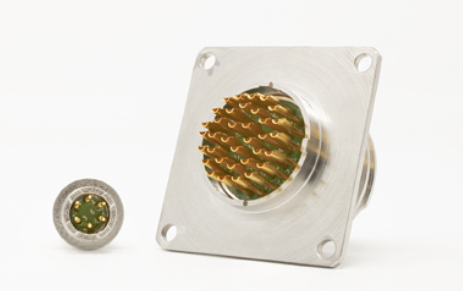

Choosing the right hermetically sealed connectors for your application

-How to determine when to use unmatched vs. matched seals

-Why glass to metal seals are often the best option for high-risk applications?

-Making the best choice for your product

What Qualifies as Hermetically Sealed?

How Does a Hermetic Seal Work?

A hermetic seal is a sealing technique designed to create an airtight and watertight barrier between two components. The process involves using materials that expand and contract at similar rates to avoid cracks and leaks due to temperature changes. Common materials include metals, glass, ceramics, and polymers. Hermetic seals are often used in electronics, aerospace, medical devices, and packaging to prevent contamination, maintain pressure, or keep components dry.

What is the Purpose of Hermetic Seal?

The primary purpose of a hermetic seal is to protect sensitive components from the external environment. In the case of electronics, this means preventing moisture and dust from damaging circuits. In aerospace or medical applications, hermetic seals are critical for maintaining the integrity of high-tech instruments that are exposed to extreme conditions such as high pressure, temperature fluctuations, and vibration. In short, a hermetic seal ensures the reliability and longevity of devices by providing airtight protection.

What Are the Different Types of Hermetic Seals?

Understanding Unmatched Hermetic Seals

Unmatched hermetic seals are those that use materials that aren’t specifically chosen for their compatibility in terms of thermal expansion, chemical resistance, or other factors. For instance, a seal may use materials like metal and rubber, but the materials may not have ideal matching properties for specific environments. While unmatched seals may be easier or cheaper to produce, they often come with compromises in terms of performance, especially in high-pressure or high-temperature environments.

Exploring Matched Hermetic Seals

Matched hermetic seals, on the other hand, use materials that are specifically selected to complement each other’s physical properties. This careful matching ensures that the materials' coefficients of expansion and other characteristics are closely aligned, preventing failure under stress or extreme conditions. Matched seals are essential when high performance, reliability, and durability are required, such as in aerospace, medical devices, and other high-risk industries. They are more expensive and complex to manufacture but provide a higher level of performance and security.

Comparing Unmatched Hermetic Seals vs. Matched Sealing Solutions

When deciding between unmatched and matched hermetic seals, the application plays a significant role. Unmatched seals might be sufficient for low-demand applications where cost is a significant concern, such as consumer-grade electronics or non-critical packaging. However, for industries requiring high performance and reliability—like aerospace, defense, or medical devices—matched hermetic seals are generally the preferred choice, as they offer superior protection against leaks, environmental factors, and temperature fluctuations.

A Deep Dive into Glass to Metal Hermetic Seals

Understanding the Key Principles in Glass to Metal Seal Design

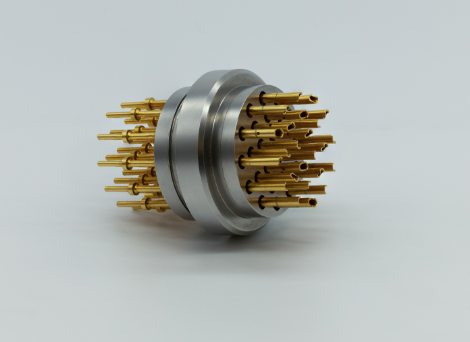

Glass to metal hermetic seals are among the most reliable sealing technologies, particularly in applications where high temperatures, extreme pressure, or electrical insulation are required. The design of a glass to metal seal requires careful selection of both materials and sealing techniques. The key principle behind glass to metal seals is the compatibility of the thermal expansion properties of both the glass and the metal. They must expand and contract at similar rates to avoid cracks or leaks. These seals are particularly useful in high-performance environments, such as in aerospace components, sensors, and vacuum tubes.

Exploring the Benefits of Glass to Metal Compression Seals

One of the most common types of glass to metal seals is the compression seal. This type of seal uses pressure to create a strong bond between the glass and metal components. The benefit of compression seals is their ability to maintain a high level of performance under varying conditions. Compression glass to metal seals are resistant to vibration, high pressure, and temperature changes, making them ideal for applications in harsh environments. Additionally, compression seals provide excellent electrical insulation, which is essential in many electronic applications.

SPCERA: Custom Hermetic Sealing Solutions

When Off-the-Shelf Hermetic Seals Aren’t Enough?

While off-the-shelf hermetic seals may work for general applications, they may not meet the specific requirements of every project. Custom hermetic sealing solutions are necessary when standard seals fail to provide the right performance characteristics, such as temperature resistance, pressure resistance, or material compatibility. Industries like aerospace, medical devices, and military applications often require custom seals that are tailored to meet unique environmental and operational conditions. Custom hermetic seals provide the ability to address special needs such as precise sizes, shapes, and performance characteristics that generic seals cannot provide.

How Glass to Metal Seals Can Be Custom-Tailored?

Glass to metal seals can be custom-tailored by selecting the right glass and metal materials for the specific requirements of the application. Factors such as the temperature range, pressure, and electrical insulation properties can be customized to suit the needs of the device. For instance, in medical devices where a high degree of sterility is required, a custom glass to metal seal can be designed to prevent contamination and ensure a tight, reliable seal. By collaborating with sealing experts, companies can create seals that not only meet technical specifications but also improve product longevity and reliability.

Benefits of Custom Seals for High-Performance Industries

Custom hermetic seals are invaluable in high-performance industries. In aerospace, for example, customized seals can ensure that components remain functional under extreme temperatures and pressures during space missions. In medical equipment, custom hermetic seals provide the airtight and sterile environment needed for sensitive components like sensors or circuits. The ability to tailor seals to specific applications allows for improved performance, reduced failure rates, and longer product lifespans.

Choosing the Right Hermetically Sealed Connectors for Your Application

How to Determine When to Use Unmatched vs. Matched Seals

The decision to use unmatched or matched hermetic seals depends on the requirements of your application. For general consumer-grade electronics or less demanding environments, unmatched seals may be sufficient. However, when high performance, reliability, and long-term durability are crucial—such as in aerospace, medical, or military applications—matched seals are necessary. To determine the right choice, assess the environmental conditions, performance requirements, and budget for your application.

Why Glass to Metal Seals Are Often the Best Option for High-Risk Applications?

Glass to metal seals are often the preferred option for high-risk applications because they offer superior protection against extreme temperatures, pressures, and other environmental factors. These seals provide a hermetic barrier that ensures no leakage, which is vital for critical systems like spacecraft, medical devices, and vacuum tubes. The durability, electrical insulation, and resistance to stress make glass to metal seals ideal for high-risk, high-performance applications where failure is not an option.

Making the Best Choice for Your Product

Choosing the right hermetically sealed connector or seal for your product involves understanding the unique needs of your application. Whether you need a standard or custom seal, consider factors such as environmental exposure, pressure requirements, and temperature conditions. By selecting the appropriate hermetic seal, you can ensure the reliability and longevity of your product while minimizing the risk of failure.

Conclusion

When choosing between unmatched hermetic seals and matched sealing solutions, it's essential to assess the specific needs of your application. While unmatched seals can be cost-effective for simpler tasks, matched seals—particularly glass to metal hermetic seals—are necessary for high-performance and high-risk industries. Custom hermetic seals, particularly glass to metal seals, offer the flexibility needed to meet the demands of advanced technologies, ensuring the longevity, durability, and functionality of your product. Always choose the seal that best fits your operational environment and performance requirements.

Recommended reading :

1.What does hermetically sealed mean?

2.What are the hermetic solutions-glass to metal seal?

3.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors