Optimizing Glass-to-Metal Seal Design for Hermetic Seals--Lead-Free Low-Temperature Sealing Glass

Release time:2025-11-19

Glass-to-metal seals are integral components for achieving hermeticity in various high-performance applications, particularly where tight sealing and long-term durability are paramount. This blog will explore the design of glass-to-metal seals, with a particular focus on lead-free low-temperature sealing glass. We will also dive into the benefits, challenges, and practical applications of these seals, especially in industries like aerospace, electronics, and medical devices. Finally, we will highlight Spcera’s advancements in low-temperature sealing glass technology, showcasing our expertise in manufacturing reliable, high-performance glass-to-metal seals.

Understanding glass-to-metal seals and their role in hermeticity

-What is a hermetic seal?

-Glass to metal seal design guide

-How glass to metal seals work step by step?

The Benefits of Lead-free low-temperature Sealing Glass for metal to glass seal

SPCERA glass to metal seal manufacturers : Low melting glass powder

-Introduction to low temperature glass powder

-List of lead-free low-temperature glass powder products

Common challenges in glass-to-metal seal design

Real-world applications of glass to metal seal in key industries

Understanding Glass-to-Metal Seals and Their Role in Hermeticity

What is a Hermetic Seal?

A hermetic seal is one that is completely impervious to gases, liquids, and other environmental factors. This is essential in applications where sensitive equipment must be protected from external elements such as moisture, air, or contamination. Hermetic seals ensure the longevity and integrity of components, preventing leaks that could lead to malfunction or failure in mission-critical systems.

In the context of glass-to-metal seals, hermeticity is achieved by combining the properties of glass and metal to form a highly durable, impermeable barrier. The glass-to-metal seal design typically uses a metal component, such as stainless steel or other alloys, and a specially formulated sealing glass that fuses with the metal surface at high temperatures.

Glass to Metal Seal Design Guide

Glass-to-metal seal design involves several important considerations:

1.Material Compatibility: Glass and metal must be chosen with compatible thermal expansion properties to ensure a reliable seal. Mismatched materials can lead to cracks or failure over time.

2.Glass Composition: The sealing glass must possess the correct viscosity, softening point, and ability to bond with metal for optimal hermeticity.

3.Manufacturing Precision: The sealing process must be precisely controlled to ensure uniformity in the glass-to-metal bond and prevent defects.

The design process typically involves choosing the right type of metal for the application, selecting the appropriate glass, and carefully controlling the temperature and atmosphere during the sealing process.

How Glass to Metal Seals Work Step by Step

Pre-sealing Preparation: The metal component and glass powder are carefully selected based on material compatibility. The metal surface may be pre-treated to enhance adhesion.

1.Glass Application: A thin layer of glass powder is applied to the metal surface or inserted in a joint.

2.Sealing Process: The glass and metal are heated together in a furnace to a specific temperature, allowing the glass to soften and bond with the metal.

3.Cooling: After the glass has bonded with the metal, the assembly is slowly cooled to room temperature to prevent thermal shock, ensuring the seal is stable and durable.

4.Final Testing: The completed glass-to-metal seal is tested for hermeticity and other performance characteristics.

The Benefits of Lead-free Low-Temperature Sealing Glass for Metal-to-Glass Seals

Incorporating lead-free low-temperature sealing glass into glass-to-metal seal design brings a number of significant advantages, especially in environments that demand high precision and strict environmental standards.

1.Environmental Compliance

Lead-free low-temperature sealing glass offers a major benefit in terms of environmental compliance. Traditional glass-to-metal seals often rely on lead-based glasses, which can be harmful to both the environment and human health. Lead-free alternatives, like Spcera’s specialized sealing glass, eliminate this risk and align with global standards such as RoHS (Restriction of Hazardous Substances), which limits the use of hazardous materials in electrical and electronic equipment.

The move to lead-free sealing glass helps businesses stay ahead of regulatory changes, meet environmental standards, and improve the sustainability of their products.

2.Low-Temperature Processing

One of the key benefits of lead-free low-temperature sealing glass is its ability to bond glass and metal at temperatures between 400°C to 500°C, as opposed to the higher temperatures required by traditional glass-to-metal seals (typically around 800°C or more). This reduced temperature processing:

1.Minimizes thermal stress on both the metal and the glass, reducing the risk of thermal shock and material damage.

2.Enables the use of temperature-sensitive components in the sealed assembly, making it ideal for advanced electronics, medical devices, and precision instruments.

3.Improved Performance and Durability

Seals made with lead-free low-temperature sealing glass offer superior hermeticity and mechanical strength, even under challenging conditions. The glass-to-metal bond created by low-temperature sealing is strong and resistant to:

Corrosion: Ideal for use in harsh chemical environments.

Mechanical Stress: The low thermal expansion mismatch between glass and metal helps prevent cracks and fractures under stress.

Temperature Fluctuations: The seals maintain their integrity across a wide range of temperatures.

Spcera Glass-to-Metal Seal Manufacturers: Low Melting Glass Powder

Introduction to Low-Temperature Glass Powder

At Spcera, we specialize in low-temperature glass powder designed for advanced glass-to-metal seal design. Our lead-free low-temperature sealing glass enables manufacturers to achieve robust, reliable seals at temperatures as low as 400°C to 500°C. This innovative material is ideal for applications where traditional high-temperature glass-to-metal sealing is impractical or detrimental to other components.

Due to material limitations and sintering conditions, certain applications cannot use high-temperature glass sealing. In these cases, Spcera’s low-temperature sealing glass provides an ideal solution, offering both excellent hermeticity and a strong bonding force between glass and metal.

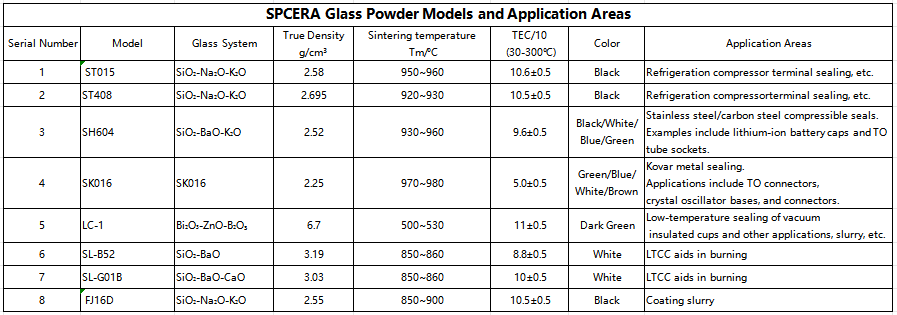

List of Lead-Free Low-Temperature Glass Powder Products

Spcera offers a range of lead-free low-temperature glass powder products, specifically designed for different industry needs. These include:

Common Challenges in Glass-to-Metal Seal Design

While glass-to-metal seal design offers several advantages, it also presents some challenges:

1.Material Compatibility: Ensuring the glass and metal have similar thermal expansion properties to avoid cracking under stress.

2.Precision in Manufacturing: Achieving uniformity in the glass-to-metal bond requires precise control of the sealing process, which can be complex.

3.Cost Considerations: Lead-free low-temperature sealing glass may come at a higher initial cost compared to traditional materials, though its long-term benefits justify the investment.

At Spcera, we address these challenges by using cutting-edge technology and quality control processes to ensure each glass-to-metal seal is reliable, durable, and cost-effective.

Real-World Applications of Glass-to-Metal Seals in Key Industries

1.Aerospace & Defense

Glass-to-metal seals are essential in aerospace and defense applications where high reliability is crucial. Spcera’s lead-free low-temperature sealing glass ensures hermetic seals in satellite sensors, communication equipment, and other high-stakes technologies that need to withstand extreme conditions.

2.Medical Devices

In the medical field, precision and safety are paramount. Glass-to-metal seals are used in devices like pacemakers, sensors, and drug delivery systems. Spcera’s low-temperature sealing glass ensures these devices maintain their hermeticity, protecting them from contamination while ensuring long-term performance.

3.Electronics & Semiconductor

The electronics industry benefits from glass-to-metal seals in components such as LED packages, power semiconductors, and circuit housings. The lead-free glass solution offers both environmental compliance and high performance in a market where both reliability and sustainability are key.

4.Energy & Industrial Applications

Spcera’s glass-to-metal seals are also used in energy production and industrial applications where high-temperature resistance and hermeticity are critical. Whether for gas turbines, electrical sensors, or power transmission components, Spcera’s low-temperature sealing glass guarantees long-lasting performance and reliability.

Conclusion

The use of glass-to-metal seal design with lead-free low-temperature sealing glass offers numerous benefits, including environmental compliance, enhanced performance, and durability, particularly for industries that demand high precision and long-term reliability. Spcera’s expertise in this area ensures that businesses can rely on our products to meet their sealing needs, offering tailored solutions that provide the best possible hermeticity and mechanical strength.

Contact Spcera today to learn more about how our glass-to-metal seal solutions can optimize your product performance and enhance your manufacturing processes.

Recommended reading

1.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors