How to Use Glass-to-Metal Seals?

Release time:2025-08-13

Glass-to-metal sealing technology is a crucial sealing method widely applied in advanced equipment, especially in harsh conditions such as extreme temperatures, high pressures, low temperatures, or vacuum environments. These seals combine the superior insulating and corrosion-resistant properties of glass with the robust strength and longevity of metals, making them ideal for sectors like energy, electronics, aerospace, and healthcare. This article provides a thorough overview of the fabrication process, application areas, benefits, and current uses of glass-metal junctions to help readers gain a comprehensive understanding of this technology.

What is a glass to metal seal?

A glass-to-metal seal is a type of bond created between glass and metal, often used in various industries where an airtight or watertight seal is needed. This bond is crucial for applications where you need to combine the properties of both materials—glass being transparent, electrically insulating, and resistant to corrosion, and metal being strong, conductive, and durable.

What is the Production Process of Glass-to-Metal Seals?

The fabrication of glass-metal seals involves a precise and intricate series of steps. From initial design and material selection to production and testing, every stage must guarantee the high quality and functionality of the final product. Below are the main steps involved in the creation of these glass-metal bonds:

Design and Material Selection

The first step in producing Glass to metal seal bonds is designing them based on their intended environment and sealing requirements, and selecting the appropriate materials. The design must account for factors such as temperature fluctuations, gas pressure changes, corrosive gases, and mechanical stress. Common metals include stainless steel, aluminum alloys, and titanium alloys, all of which offer excellent resistance to corrosion and high-temperature performance. When choosing glass materials, their thermal expansion coefficient must align with the metal's properties, with commonly used materials being lead glass, soda-lime glass, and specialized ceramic glass. For specialized uses, design guides for glass-metal junctions are frequently employed to ensure compatibility.

Metal Surface Treatment

Surface preparation of the metal is an essential step to ensure proper bonding between the glass and the metal. First, the metal surface is cleaned to remove impurities such as oxides, oils, and other contaminants. This is typically achieved through acid washing, sandblasting, or ultrasonic cleaning. Coating treatments on the metal surface further enhance the adhesion between the glass and metal. Ensuring a smooth metal surface with a certain level of reactivity allows the glass to bond securely with the metal.

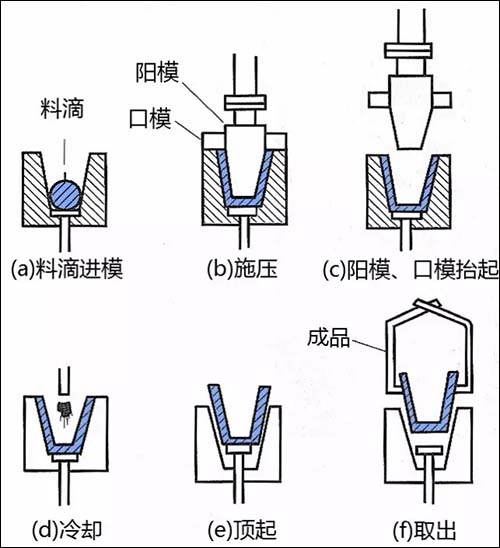

Glass Formation

The process of shaping the glass is crucial for producing a reliable glass-metal junction. The glass needs to be heated and formed into the desired shape, with techniques like glass blowing, drawing, or molding employed to meet the sealing requirements. The thickness and smoothness of the glass surface must be controlled precisely to ensure that its thermal expansion properties align with those of the metal.

Preparing Glass and Metal for Bonding

Before joining the glass and metal, both materials undergo special treatments to ensure effective bonding at high temperatures. This includes cleaning and heating the metal and pre-treating the glass. The heating process helps remove internal stresses and optimizes the bonding strength between the glass and the metal. It is crucial that both materials are free from contaminants to ensure optimal sealing performance.

Heat Treatment and Annealing

Heat treatment and annealing are applied to alleviate internal stresses between the glass and metal. Due to the differences in thermal expansion rates, annealing helps maintain the stability and durability of the seal. The precise control of these processes improves the bonding strength between the materials, ensuring that the joint maintains performance even in high-temperature environments.

Finally, glass-metal bonds undergo stringent testing and quality assurance procedures. Common tests include leak detection, mechanical performance evaluations, thermal cycling, and surface defect inspections. The quality control process ensures that each seal adheres to design specifications and can reliably operate in harsh conditions over extended periods.

What Are the Application Scenarios for Glass-to-Metal Seals?

Glass-to-metal seals are used in a wide range of high-demand applications, providing exceptional sealing performance that ensures the long-term stability and safety of equipment. Below are some typical application areas for this sealing technology:

Sealant Glass Powder

Glass sealant powders are commonly used for sealing terminal pins on air conditioner and refrigerator compressor terminals. These materials perform comparably to imported glass sealants from Japan and the United States, maintaining effective sealing performance in high-temperature and high-pressure environments. These sealants provide excellent electrical insulation properties, preventing current leakage, and offer strong corrosion resistance to extend the lifespan of the equipment.

Low-Temperature Co-Fired Glass

Low-temperature co-fired glass technology is used extensively in the electronics industry, especially in the production of filters and ceramic antennas for high-frequency devices. By enhancing the density of ceramics, this co-firing technology improves the mechanical and dielectric properties of the product, boosting the performance and reliability of electronic devices. It also improves the device’s immunity to interference, enabling high-precision signal transmission.

Lithium-Ion Battery Cap Sealing

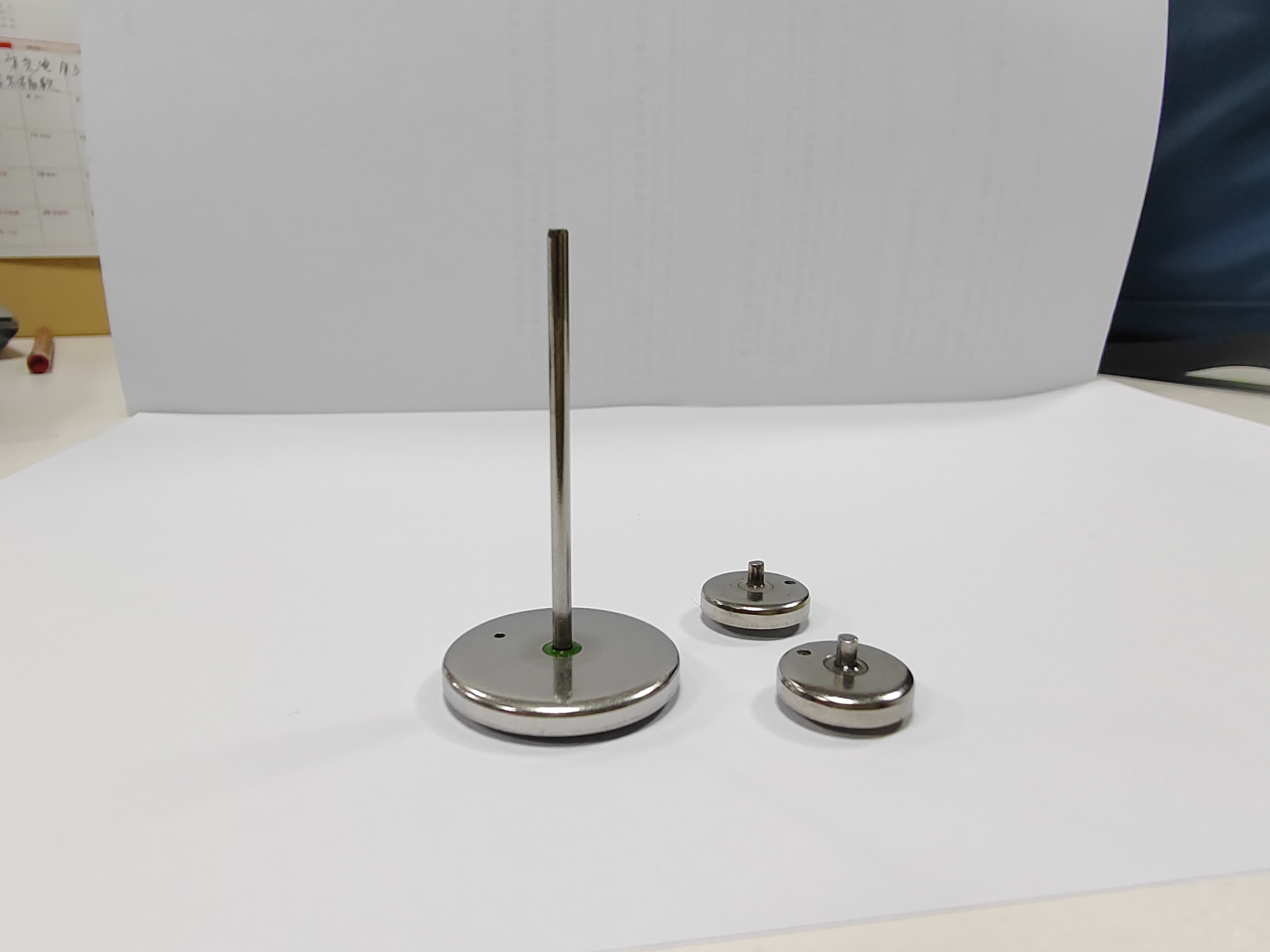

Glass-to-metal bonding technology plays a crucial role in lithium-ion batteries. It prevents leakage and corrosion of electrolytic fluid, ensuring a battery lifespan of 10 to 15 years. SINOPRIDE achieves a sealant yield rate of 99.7% for battery caps, improving the safety and stability of the batteries. In this common application, glass-metal connectors play a vital role in ensuring electrical safety.

What Are the Advantages of Using Glass-to-Metal Seals?

When compared to other sealing technologies, glass-metal junctions offer several distinct advantages. Below are the key benefits of using glass-to-metal bonds:

Sealing Performance

Glass-metal bonds provide exceptional sealing capabilities, effectively preventing the leakage of gases, liquids, or contaminants. This makes them ideal for applications that demand extremely high sealing performance. Their superior sealing properties ensure the stable and long-term operation of equipment in environments with high pressure, high temperature, or vacuum conditions. This is especially vital in aerospace or in high-pressure applications where glass-metal junctions are used in critical systems.

Thermal and Electrical Insulation

In addition to sealing, the combination of glass and metal provides outstanding thermal and electrical insulation properties. This makes glass-metal junctions ideal for use in electronic devices, spacecraft, battery enclosures, and other high-tech applications that require electrical and thermal isolation. How to apply liquid glass metallic seals is an important step in optimizing these insulation properties for complex applications.

Durability and Extended Lifespan

Glass-metal junctions are highly resistant to corrosion and heat, allowing them to function reliably in extreme environments for prolonged periods. Their longevity far exceeds that of many conventional sealing technologies, making them ideal for applications requiring high reliability and durability. Manufacturers of glass-metal junctions are dedicated to offering robust solutions that prolong the lifespan of critical equipment.

Moisture and Contamination Resistance

The structure of glass-metal seals effectively blocks the entry of moisture and contaminants from the outside, thereby safeguarding internal components from humidity and pollution. This moisture and contamination resistance makes them ideal for use in medical devices, precision instruments, and other applications where stable and reliable operation is required.

Latest Applications of Glass-to-Metal Seals

With ongoing technological advancements, the range of applications for glass-metal seals continues to grow, particularly in the fields of new energy and healthcare.

New Energy

In sectors like electric vehicles and air conditioning, glass-to-metal seals are widely used in applications such as talc ceramic beads, high-power industrial air conditioning, and home air conditioning systems. These seals offer excellent sealing performance even under extreme temperature fluctuations and high-pressure environments, ensuring the efficiency and extended lifespan of both air conditioning and battery systems.

Healthcare

In healthcare, glass-metal seals are critical for sealing lithium-ion batteries and medical implant devices. The combination of glass and metal ensures the long-term safety and stability of batteries, preventing electrolyte leakage. For medical implants, these seals provide high sealing performance and contamination resistance, ensuring the safety and durability of devices implanted in the human body. Military-grade glass-metal connectors are also crucial in defense-related applications.

As a leading high-performance sealing technology, glass-metal junctions have been widely adopted across numerous industries. From new energy and medical devices to aerospace and precision instruments, glass-metal sealing technology is the go-to choice for high-end applications, thanks to its exceptional performance and unique advantages.

SINOPRIDE , a renowned manufacturer of glass-to-metal seals, is committed to providing premium, high-performance sealing solutions to clients worldwide. With years of accumulated expertise and continual innovation, SINOPRIDE has achieved significant success in areas such as new energy, healthcare, and electronics, and will continue to drive the evolution of glass-to-metal sealing technology.

Recommended reading :

1.What does hermetically sealed mean?

2.Introduction to the world's top glass-to-metal seal manufacturers

3.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors