Introduction to the world's top glass-to-metal seal manufacturers

Release time:2025-08-19

Glass-metal seals are high-performance sealing solutions made from glass and metal, widely used in aerospace, military, electronics, power, and medical industries. Their key characteristics include high temperature resistance, corrosion resistance, high reliability, excellent electrical insulation, and precise micro-manufacturing. The global market for glass-metal seals is valued at over $3 billion annually, with expected continued growth.

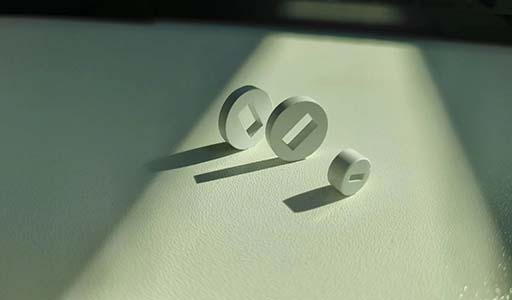

What Are Glass-Metal Seals?

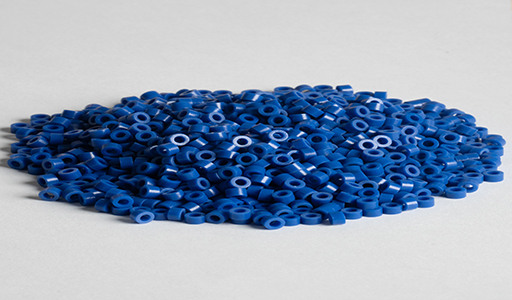

Glass-metal seals are sealing solutions widely used in high-tech fields, primarily made of glass and metal. The working principle involves melting the glass and sealing it between metal interfaces, creating a strong, high-temperature resistant, and corrosion-resistant sealing structure. Glass-metal seals are commonly used in aerospace, military, electronics, power, and medical industries, offering exceptional sealing performance, especially under extreme conditions where they maintain stable operation.

According to market research, the global annual output value of glass-metal seals has exceeded $3 billion, with an expected continuous growth rate of around 6% in the coming years. This growth is primarily driven by diversified demand and technological advancements, particularly in the fields of microelectronics and high-performance devices.

Applications of Glass-Metal Seals

Characteristics of Glass to Metal Seal

Glass-metal seals have a series of superior features that make them ideal for high-end sealing applications. The key characteristics are as follows:

High-Temperature Resistance: Glass-metal seals can withstand extremely high temperatures, typically operating within the range of -200°C to +400°C, and in extreme cases, they can even tolerate up to +800°C.

Corrosion Resistance: The combination of metal and glass gives the seals excellent resistance to many chemicals and acid-base environments.

High Reliability: The complementary physical properties of glass and metal materials make the sealing structure very stable, with a long service life and minimal maintenance required.

Excellent Electrical Insulation: These seals have excellent electrical insulation properties, making them widely used in the electronics and power industries, particularly in high-voltage and high-frequency environments.

Precise Micro-Size Manufacturing: Modern manufacturing techniques allow glass-metal seals to be produced in extremely precise sizes, meeting the needs of various precision instruments and equipment.

Specific Application Scenarios of Metal to Glass Seal

Aerospace:

In the high-demand aerospace sector, including satellites, rockets, and aircraft, glass-metal seals are used to connect electronic components, optical fiber connectors, pressure sensors, etc., ensuring stable performance in extreme environments.

Electronics:

Glass-metal seals are particularly useful in high-frequency circuits, LED packaging, capacitors, and battery packaging, where they effectively isolate electrical currents and protect internal electronic components from external interference.

Medical Devices:

Glass-metal seals are used in implantable medical devices and life-monitoring equipment, ensuring that the devices maintain sealing integrity in complex environments and reducing the impact on the human body.

Energy and Oil

Glass-metal seals are also applied in oil drilling, high-temperature boilers, and nuclear facilities, helping to solve sealing problems in high-temperature, high-pressure, and highly corrosive environments.

Glass-Metal Sealing Manufacturers Worth Watching

Glass-metal seals play a crucial role in many high-tech industries, particularly in electronics, aerospace, and automotive sectors. Their unique sealing properties, along with their high-temperature resistance and corrosion resistance, make them essential components. Below are three competitive manufacturers in the field of glass-metal seals — SCHOTT, Japan NEG, and SINOPRIDE— each leveraging their technological strengths and innovative applications to maintain a significant position in the global market.

SCHOTT

Headquarters: Germany

Established: 1889

Overview: SCHOTT AG is a global leader in glass and glass-ceramic products, offering a wide range of high-tech glass products, including glass-metal seals. Its products are widely used in electronics, medical, optoelectronics, and aerospace sectors, particularly excelling in high precision and high stability.

Key Areas: SCHOTT’s glass-metal seals are vital in several high-end fields, particularly in optoelectronics, semiconductors, and medical devices. With superior high-temperature and corrosion resistance, SCHOTT provides long-lasting sealing solutions. Additionally, SCHOTT is dedicated to offering efficient and reliable seals for the aerospace and automotive industries.

Deployment Scenarios: SCHOTT has research centers and production bases in multiple countries and regions, with a broad presence in Europe, North America, and Asia. Its technologies are not only used in traditional sectors but are also widely applied in emerging industries such as smart devices and advanced medical equipment, showcasing its strong global competitiveness.

Headquarters: Tokyo, Japan

Established: 1949

Overview: Nippon Electric Glass Co., Ltd. (NEG) is a renowned global glass manufacturer, specializing in electronic glass, specialty glass, and glass-metal seals. NEG’s glass-metal seals are widely used in electronics, aerospace, and other fields, known for their excellent precision, stability, and durability.

Key Areas: NEG’s glass-metal seals are primarily used in aerospace, energy, and communications. Thanks to their stability under high temperatures and pressures, NEG's sealing technologies are extensively applied in satellite communications, electronic devices, and precision instruments, ensuring the long-term safety and stable operation of these products.

Deployment Scenarios: NEG has a robust global production and sales network, with a significant presence in Asia and North America. Through continuous technological innovation, NEG ensures that its products remain at the forefront of the industry, meeting the diverse performance demands of various sectors.

SINOPRIDE

Headquarters: Shenzhen, China

Established: 2013

Overview: SINOPRIDE is a high-tech enterprise specializing in glass-metal seals and ceramic technologies. With its leading research and development capabilities and exquisite manufacturing processes, the company is committed to providing high-quality sealing solutions for a variety of industrial applications.

Key Areas: glass-metal seals are primarily used in electronics, power, communications, and high-end manufacturing sectors. Its products are widely applied in electronic devices, LED packaging, and automotive sensors, particularly excelling in high-temperature resistance and corrosion resistance.

Deployment Scenarios: SINOPRIDE’s products have already been applied in several high-end markets within China and are gradually expanding into overseas markets, particularly in Asia and Europe. The company continues to enhance its global competitiveness through ongoing technological innovation and quality optimization, aiming to become an industry leader in glass-metal seals.

These three companies each have unique characteristics in the glass-metal sealing field, securing important positions in the industry through advanced technology and strong market presence.

Manufacturing Costs of Metal Seals

Glass to Metal Seal Supplier

The main suppliers of glass-metal seals are concentrated in Europe, the U.S., and Asia, with the most notable suppliers including SCHOTT, Corning, and Caterpillar. These suppliers offer customized services to meet the diverse needs of various industries.

Glass Metal Sealing Cost

The production cost of glass-metal seals is influenced by various factors, including material costs, manufacturing processes, and customization requirements. Generally, seals with standard sizes and for conventional applications are relatively inexpensive, but customized seals made from special materials or requiring complex manufacturing processes may cost several hundred to thousands of dollars.

Glass Metal Seals Price

The price of glass-metal seals typically ranges from $20 to $2,000, depending on factors such as size, material, precision, and order quantity. Bulk orders often come with discounts, while small-batch or custom products may significantly increase in price. Market research shows that the price of glass-metal seals has generally increased, particularly in high-end electronics and aerospace sectors.

While globally renowned brands like SCHOTT offer high-quality glass-metal seals, the SINOPRIDE brand provides more affordable products thanks to advanced manufacturing processes and reasonable production costs. SINOPRIDE has deep technical expertise in glass-metal sealing technology, offering cost-effective sealing solutions to clients, especially when meeting the demand for mass production while maintaining high quality and precision.

In summary, glass-metal seals play an essential role in many high-tech industries. With advancements in technology and increasing market demand, the application prospects of glass-metal seals are vast. By selecting the right supplier, businesses can access high-performance and competitively priced sealing solutions.

Recommended Reading

1.What Is a Glass to Metal Seal?