What Are the Hermetic Solutions: Glass to Metal Seal

Release time:2025-08-21

Glass-to-metal sealing technology is a specialized solution for high-precision, high-reliability sealing applications, widely used in aerospace, nuclear energy, power generation, and electronics. The advantages of glass-to-metal seals include high temperature and pressure resistance,excellent chemical stability, and long service life, making them effective in extreme environments. This article will detail the basic concept of sealing technology, the importance of customized sealing solutions, the definition and benefits of glass-to-metal seals, specific application examples, and explore the irreplaceable role of this technology in modern industries.

What is Sealing Technology?

Sealing technology refers to the use of various sealing materials and techniques to form an effective barrier at the junctions of equipment and containers, preventing the leakage of fluids, gases, or particles. Whether in mechanical devices, chemical reactors, or high-precision electronic products, sealing plays a crucial role in ensuring the safe operation and long-term stability of equipment.

Among the various sealing methods, common types include O-ring seals, gasket seals, and piston seals. Glass-to-metal sealing, as a special sealing technology, offers advantages such as high temperature, high pressure, and corrosion resistance, making it ideal for applications in environments with higher sealing requirements.

Customized Sealing Solutions

Sealing needs vary by industry and application environment. For instance, in high-temperature, high-pressure, or extreme environments, common sealing materials may not be sufficient, making customized sealing solutions essential. Custom sealing solutions consider multiple factors, such as material selection, seal shape, and operating conditions (temperature, pressure, and chemical media).

Benefits of Custom Sealing Solutions include:

Highly Specific:

Tailored to meet the specific operating environment and application needs, ensuring the most suitable materials and designs are used.

Improved Equipment Performance:

Customized seals can effectively extend the service life of equipment, reduce failure rates, and improve operational efficiency.

Safety Assurance:

In industries like aerospace and nuclear energy, sealing technology directly impacts the safety and stability of equipment, making custom sealing solutions crucial.

For example, in aerospace, seals need to withstand extreme temperatures, pressures, and radiation, conditions that ordinary rubber or plastic seals cannot endure. Therefore, customized glass-to-metal seals are essential for ensuring long-term stable operation.

What is Glass-to-Metal Sealing?

Glass-to-metal sealing is a technology that combines glass and metal materials to create a seal. The key principle behind this technology is the difference in the expansion coefficients of glass and metal, which forms a stable bond at the sealing interface, ensuring an effective seal. This sealing method is especially suitable for high-temperature, high-pressure, corrosive, or vacuum environments, offering long-lasting performance.

Compared to traditional sealing materials, glass-to-metal seals offer several key advantages:

High Temperature Resistance:

Glass-to-metal seals can withstand temperatures above 1000°C, making them suitable for extreme heat conditions.

High Pressure Resistance:

These seals can operate effectively under high pressure, ensuring stability and reliability.

Chemical Stability:

The combination of glass and metal provides excellent corrosion resistance, capable of withstanding exposure to strong acids, alkalis, and other aggressive chemical media.

Excellent Electrical Insulation:

Glass-to-metal seals provide excellent electrical insulation, making them widely used in electronics and semiconductor industries.

Benefits of Glass-Metal Sealing Solutions

Glass-metal sealing technology, known for its excellent high-temperature and high-pressure resistance, chemical stability, and long lifespan, is widely used across various industries, particularly in applications requiring high reliability and extreme operating conditions. Below are specific examples and scenarios where glass-metal sealing solutions are applied:

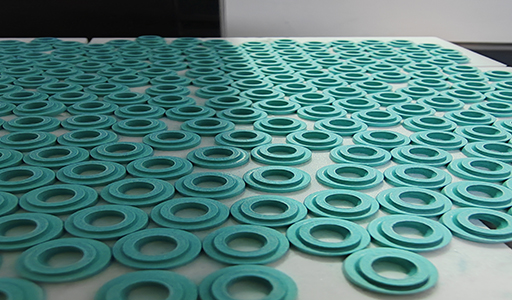

Refrigerator Compressor Terminals

In refrigerator and air conditioner compressors, the terminals are critical components for maintaining airtightness. Any gas leakage can lead to decreased efficiency or equipment failure. Traditional rubber or plastic sealing materials often cannot withstand high temperature and pressure environments. Glass-metal sealing provides an ideal alternative. It effectively isolates the internal and external gas exchange within the compressor, ensuring its stability in high-temperature environments.

Application Scenario: In household refrigerators or commercial refrigeration units, compressors need to endure frequent start-stop cycles while operating under high temperature and pressure conditions. Glass-metal seals ensure that compressor terminals remain leak-free, extend the compressor's lifespan, and improve overall equipment reliability and performance.

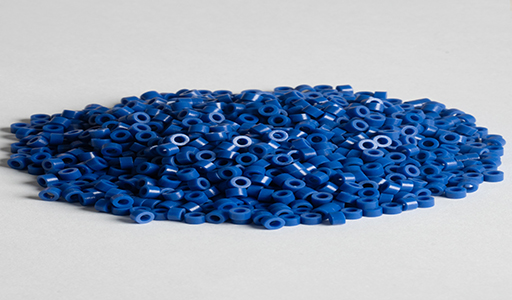

Lithium Thionyl Chloride Battery

Lithium thionyl chloride batteries are commonly used in high energy-density, long-term storage applications, such as remote sensing equipment, spacecraft, and military electronics. To ensure the safety and long-term stability of the batteries, glass-metal seals are applied to the battery's packaging. These seals effectively prevent the leakage of internal gases or electrolytes, and they can perform stably in extreme temperature changes and high-pressure environments.

Application Scenario: Lithium thionyl chloride batteries are used in applications requiring high stability and long lifespan, such as telemetry equipment, satellites, and deep space probes. In these advanced applications, any leakage from the battery could affect the overall operation of the device. Glass-metal seals ensure the battery operates reliably in extreme external environments, safeguarding the long-term functioning of the equipment.

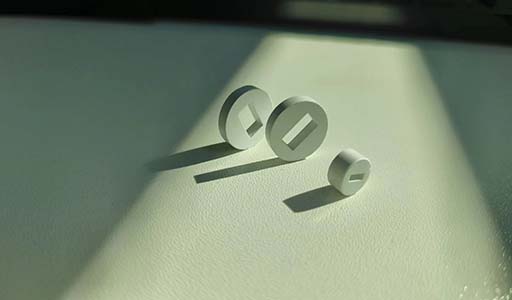

Glass Preforms

Glass preforms are an important application area for glass-metal sealing technology, often used in sealing demands in high-temperature and vacuum environments. In equipment that requires combining glass and metal, glass-metal sealing provides excellent airtightness and long-term stability. Glass preforms help maintain sealing performance during high-temperature operations, especially in the production of electronics, semiconductors, and high-tech devices.

Application Scenario: Glass-metal sealing technology is widely used in optical fibers, vacuum tubes, and laser devices, particularly in fields that require strict temperature, vacuum, and pressure conditions. By forming a strong bond between the metal surface and glass, glass-metal seals ensure that the devices can operate stably under high-pressure, vacuum, or high-temperature conditions, extending the lifespan of the equipment.

Glass-metal sealing technology, with its high-temperature and high-pressure resistance, chemical stability, and long lifespan, is indispensable in various high-demand sectors, including refrigerator compressor terminals, lithium thionyl chloride batteries, and glass preforms. Whether ensuring airtightness, improving equipment reliability, or prolonging the lifespan of devices, glass-metal sealing solutions demonstrate irreplaceable advantages. As industrial demands for sealing technology continue to rise, glass-metal seals will continue to play a crucial role, providing efficient and reliable sealing solutions across industries.

Sealing Solutions Group

Sealing Solutions Group was founded in 1995 and is headquartered in the United States. The group is a global leader in providing sealing technologies and solutions. With branches and subsidiaries in multiple countries, Sealing Solutions Group is committed to delivering high-quality, reliable, and customized sealing solutions to customers across various industries, including aerospace, nuclear energy, petrochemical, and electronics.

The core services of Sealing Solutions Group include:

Sealing Technology R&D and Design:

Offering custom sealing solutions that meet the needs of different industries.

Glass-to-Metal Seal Supply:

Providing high-performance glass-to-metal sealing technologies, especially suitable for high-temperature, high-pressure, and corrosive environments.

Engineering Consulting and Technical Support:

Providing comprehensive support throughout the sealing process, from design and material selection to installation and commissioning.

Quality Inspection and After-Sales Service:

Offering complete quality testing systems to ensure every seal meets industry standards.

Glass-to-metal sealing technology, as an innovative and efficient sealing solution, offers exceptional resistance to high temperatures, high pressures, chemical stability, and long service life. It is widely used in high-end industries such as aerospace, nuclear energy, and power generation. Customized sealing solutions can be designed to meet specific industry requirements, ensuring the safety and long-term stability of equipment.

As a leading brand in the industry, SINOPRIDE has made significant achievements in various fields through its advanced glass-to-metal sealing technology and strong R&D capabilities. As the demand for high-performance sealing components continues to grow, SINOPRIDE will remain committed to innovating and developing glass-to-metal seals to provide more reliable and secure sealing solutions to global customers.

Recommended reading :

1.What does hermetically sealed mean?