Top Glass-to-Metal Seal Manufacturers and Suppliers in Asia Pacific by 2025

Release time:2025-09-22

Glass-to-metal seals are an essential technology in various industries, ensuring the protection and longevity of sensitive equipment and devices. These seals, which create a hermetically sealed barrier between glass and metal, play a pivotal role in applications requiring airtight, watertight, and contamination-free environments. From medical implants to aerospace components, these seals are designed to maintain the integrity of sensitive systems under extreme conditions, such as temperature fluctuations, pressure variations, and exposure to corrosive elements.

What does hermetically sealed mean?

-When is hermetic really hermetic?

-What is the difference between airtight and hermetically?

How to make hermetic seal?

-How long do hermetic seals last?

-What are the hermetic solutions: glass to metal seal

Specific application types of glass-to-metal seals

-Sealed lithium batteries for medical implants

-Application of oxygen sensor gaskets in the automotive industry

Best glass to metal seal manufacturers in Asia Pacific

Why Choose Spcera as Your Reliable Glass to Metal Seal Supplier?

-Glass to metal seal design

-Custom glass-to-metal-sealed connector

Asia Pacific Glass to Metal Sealing Technology and Services Market Direction 2025

-Asia Pacific Glass-to-Metal Seals Market: Size, Trends, and Forecasts

-Glass-to-Metal Sealing Technology in Asia Pacific

-Asia pacific glass to metal sealing technology price

-What element is used for glass to metal seals?

-Are lithium thionyl chloride batteries safe?

-What is the glass to metal seal market?

Conclusion

What Does Hermetically Sealed Mean?

A hermetic seal refers to a sealing method that prevents any exchange of gases, liquids, or contaminants between two environments. Specifically, in the context of glass-to-metal seals, it means the joint between glass and metal is perfectly airtight and watertight, ensuring that no external elements can infiltrate the sealed environment. This makes hermetic seals crucial for preserving the functionality and safety of devices in challenging environments, where even the smallest leak can cause failures.

When Is Hermetic Really Hermetic?

The term "hermetic" can be misleading when used loosely. In its truest sense, a hermetic seal is a complete barrier against any exchange of gases, moisture, particles, or other contaminants. A truly hermetic seal must meet stringent quality standards, including material compatibility, reliable construction, and long-term performance in varying conditions. For high-performance applications, such as medical devices, aerospace equipment, or scientific instruments, the hermetic seal must maintain its integrity for many years, ensuring safety, functionality, and durability.

What Is the Difference Between Airtight and Hermetically Sealed?

Both airtight and hermetically sealed systems aim to prevent air from escaping or entering, but there is a crucial distinction between the two. While "airtight" simply prevents air leakage, it does not necessarily stop moisture, dust, or other environmental contaminants from entering the sealed area. On the other hand, a "hermetically sealed" system is impermeable not only to air but also to gases, liquids, and even microorganisms, offering a higher level of protection. Hermetic seals provide a more robust and reliable solution for applications where contamination could lead to device failure or health risks, such as in medical implants and military equipment.

How to Make a Hermetic Seal?

Creating a hermetic seal requires careful selection and processing of materials, along with precise manufacturing techniques. The key to a successful glass-to-metal seal lies in the compatibility of the glass and metal materials, particularly in terms of their thermal expansion properties. Since glass and metal expand and contract at different rates when subjected to temperature changes, ensuring that these materials can withstand such stresses is essential for maintaining the seal's integrity over time.

The process of creating a hermetic seal typically involves bonding glass and metal through the application of heat and pressure. The materials must be carefully selected to ensure they provide the necessary mechanical strength and resistance to thermal cycling, corrosion, and other environmental stresses. Once the seal is formed, additional testing is often conducted to ensure that the bond remains leakproof under various conditions.

How Long Do Hermetic Seals Last?

The lifespan of a hermetic seal depends on several factors, including the materials used, environmental conditions, and the specific application. In general, hermetic seals are designed to last for decades, often withstanding harsh conditions without degradation. For example, seals in medical implants, such as pacemakers or neural stimulators, may need to last for a minimum of 20 years. In industrial applications, seals may experience varying lifespans depending on factors like temperature extremes, radiation, and exposure to corrosive substances.

Even though hermetic seals are built for longevity, certain extreme conditions can still lead to seal degradation. Over time, exposure to very high temperatures, ionizing radiation, or aggressive chemicals can weaken the seal, causing it to lose its protective properties. As such, regular monitoring and testing are important in ensuring the ongoing reliability of hermetically sealed components.

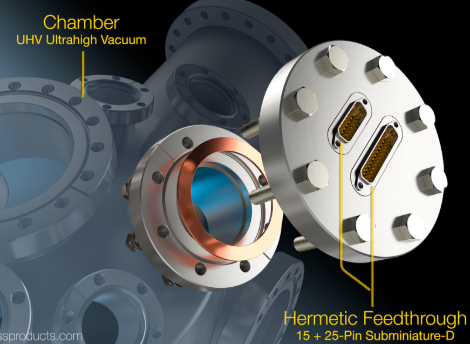

What Are the Hermetic Solutions: Glass to Metal Seal?

Glass-to-metal seals offer a highly reliable hermetic solution by creating a permanent bond between glass and metal. These seals are used in a wide range of industries, from aerospace and automotive to electronics and medical devices. Glass-to-metal seals can be found in various products, such as vacuum tubes, sensors, electrical connectors, and medical implants. The technology ensures that these components remain sealed and protected from external elements, thereby enhancing their performance and durability.

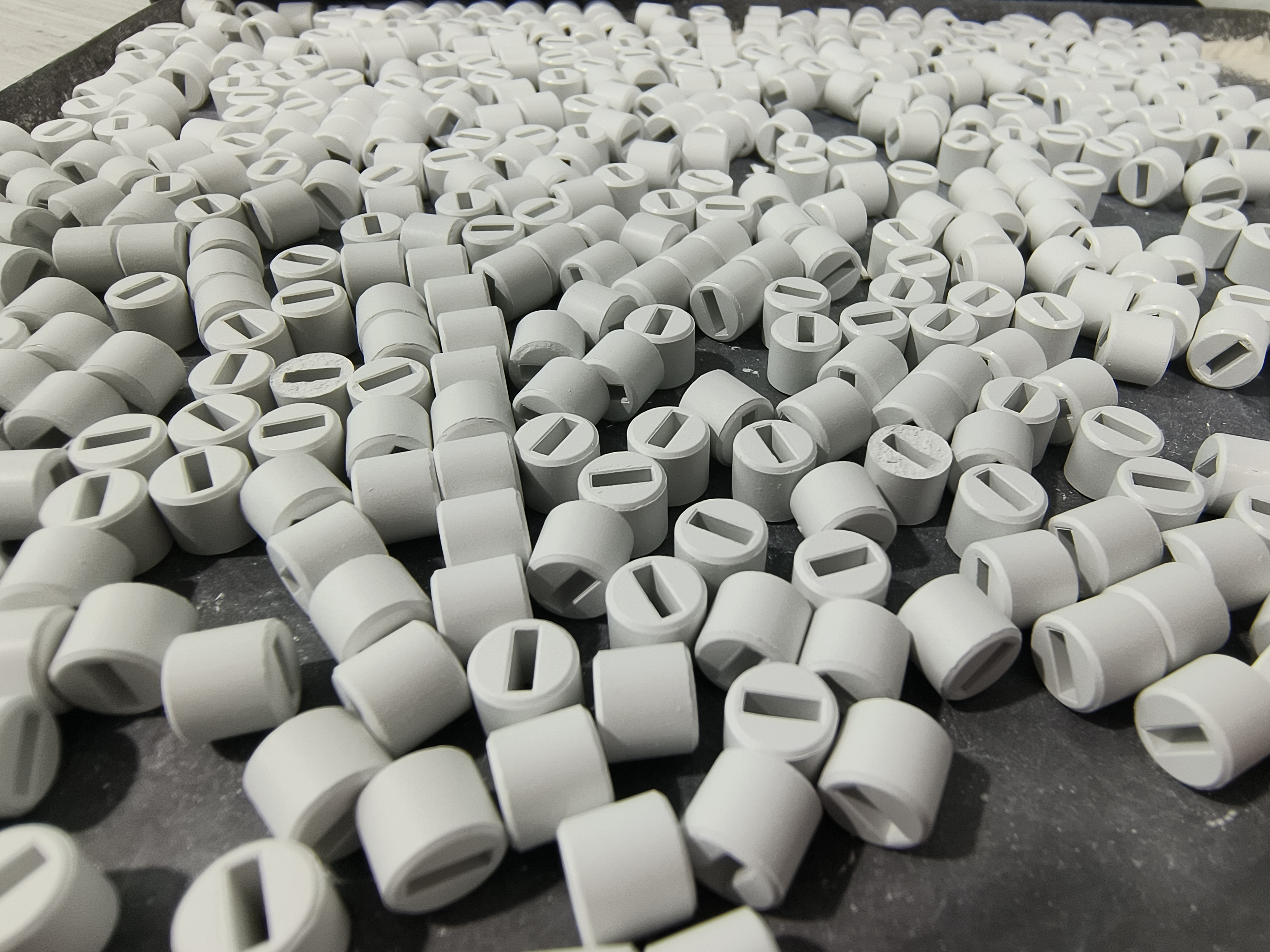

Specific Application Types of Glass-to-Metal Seals

Glass-to-metal seals are used in diverse applications, each with specific requirements for durability, performance, and longevity. Some of the most common and critical applications include:

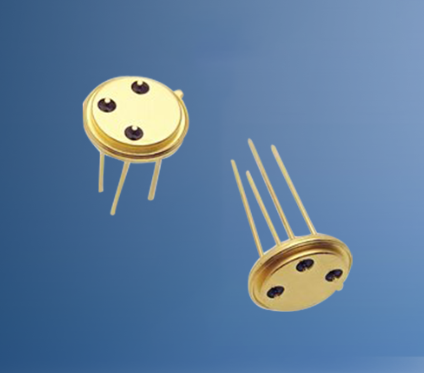

Sealed Lithium Batteries for Medical Implants

Lithium batteries, commonly used in medical implants like pacemakers and neural stimulators, require hermetically sealed enclosures to protect their internal components. These batteries need to operate for extended periods, often decades, without exposure to moisture or air, which could cause them to malfunction. Glass-to-metal seals are ideal for this application due to their exceptional durability and ability to create an airtight and moisture-proof seal, ensuring that the battery's internal components remain intact throughout its lifespan in the human body.

In medical devices, where the safety of the patient is paramount, the reliability of the hermetic seal is crucial. A failure in the seal could lead to battery leakage, reduced performance, or even device failure, potentially putting the patient's health at risk. Therefore, the longevity and integrity of these seals are critical factors in the design and manufacturing of medical implant batteries.

Application of Oxygen Sensor Gaskets in the Automotive Industry

Oxygen sensors are vital components in modern vehicles, playing a key role in ensuring proper fuel combustion and reducing emissions. These sensors must operate efficiently in high-temperature environments and in the presence of corrosive exhaust gases. Glass-to-metal seals are used to encase the sensor components, preventing moisture, gases, and dirt from interfering with sensor functionality.

In the automotive industry, where emission standards are becoming increasingly stringent, the performance of oxygen sensors is critical. A reliable glass-to-metal seal ensures that the sensor can maintain its accuracy and longevity, even under the most demanding conditions, such as high temperatures and exposure to corrosive exhaust gases.

Best Glass-to-Metal Seal Manufacturers in Asia Pacific

The Asia Pacific region is home to several leading manufacturers of glass-to-metal seals. These companies supply high-quality sealing solutions for a variety of industries, including aerospace, automotive, medical, and electronics. Below is a list of some of the top glass-to-metal seal manufacturers and suppliers in the region:

|

Company |

Key Products |

Core Advantages |

Application Areas |

Certifications/Standards |

|

Spcera |

Glass-to-metal sealed connectors, hermetic feedthroughs |

Custom design, high quality, precision manufacturing |

Medical, automotive, aerospace |

ISO 9001, RoHS, CE, UL |

|

Kovar Technologies |

Glass-to-metal seals, ceramic-to-metal seals |

Precision engineering, specialized in high-stress environments |

Space, military, medical |

ISO 13485, AS9100, RoHS |

|

Nippon Mektron |

Glass-to-metal seals, metal feedthroughs |

Innovative sealing solutions, long lifespan |

Electronics, telecommunications |

ISO 9001, IATF 16949, RoHS |

|

Schott AG |

Glass-to-metal seals, glass frits |

High thermal stability, precision design |

Aerospace, automotive, medical |

ISO 9001, ISO 14001, UL |

|

Molex |

Hermetically sealed connectors, sensors |

High reliability, advanced design capabilities |

Consumer electronics, automotive |

ISO 9001, RoHS, IATF 16949 |

|

CeramTec |

Ceramic-to-metal and glass-to-metal seals |

Strong mechanical strength, high precision |

Industrial, medical, electronics |

ISO 9001, ISO 13485, RoHS |

Why Choose Spcera as Your Reliable Glass-to-Metal Seal Supplier?

Spcera is one of the leading manufacturers of glass-to-metal seals in the Asia Pacific region, known for its high-quality and customizable sealing solutions. Here’s why you should consider Spcera for your hermetic sealing needs:

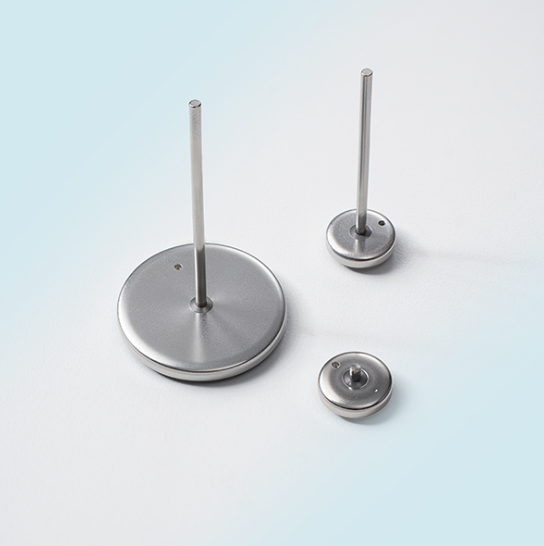

Glass-to-Metal Seal Design

Spcera specializes in designing innovative glass-to-metal seals tailored to meet the specific needs of each client. Whether it’s for a high-temperature application in the aerospace industry or a medical-grade implant, Spcera’s design team ensures that each solution is durable, cost-effective, and meets the most stringent standards. Their expertise allows them to create custom solutions that are perfectly aligned with the customer’s requirements, providing optimal performance and reliability.

Custom Glass-to-Metal-Sealed Connector

In addition to its glass-to-metal seals, Spcera also offers custom glass-to-metal sealed connectors. These connectors are designed to operate efficiently in harsh environments, including medical implants, automotive sensors, and aerospace components. With advanced technology and a wide range of customization options, Spcera ensures that each product meets the highest industry standards for performance, durability, and quality.

Asia Pacific Glass-to-Metal Sealing Technology and Services Market Direction 2025

The glass-to-metal sealing technology market in the Asia Pacific region is expected to experience substantial growth by 2025. As industries such as medical devices, automotive, aerospace, and electronics continue to expand, the demand for high-performance sealing solutions will increase. The region is anticipated to remain at the forefront of technological advancements in sealing processes, offering enhanced materials, improved bonding technologies, and innovative sealing solutions.

Asia Pacific Glass-to-Metal Seals Market: Size, Trends, and Forecasts

The market for glass-to-metal seals in Asia Pacific is projected to grow significantly due to the rising demand in various sectors. The expansion of the automotive industry, the increasing prevalence of medical implants, and technological advancements in consumer electronics are all contributing factors. Additionally, the demand for high-performance seals in aerospace, military, and industrial applications is further driving market growth.

Glass-to-Metal Sealing Technology in Asia Pacific

In the coming years, glass-to-metal sealing technologies will continue to evolve, with advancements in manufacturing processes, material selection, and automation. Improved bonding techniques and better material properties are enabling the development of more cost-effective and reliable sealing solutions. The development of new materials with higher thermal stability, electrical conductivity, and corrosion resistance will be a key trend in the market.

Asia Pacific Glass-to-Metal Sealing Technology Price

As manufacturing processes become more efficient and economies of scale come into play, the price of glass-to-metal sealing technology is expected to decrease. Although prices may fluctuate depending on material costs and manufacturing complexity, the overall trend indicates a reduction in cost, making high-quality hermetic seals more accessible to a wider range of industries.

FAQs

What element is used for glass to metal seals?

The primary metals used for glass-to-metal seals include Kovar (Fe-Ni-Co alloy), stainless steel, copper, and aluminum. These metals are chosen for their ability to match the thermal expansion properties of glass, ensuring a durable, hermetic bond.

Are lithium thionyl chloride batteries safe?

Lithium thionyl chloride (LiSOCl₂) batteries are generally safe when used as intended, offering long life and high energy density. However, they can be hazardous if exposed to extreme conditions, such as overcharging or physical damage, which could cause leakage or rupture, releasing toxic substances.

What is the glass to metal seal market?

The glass-to-metal seal market refers to the industry focused on manufacturing seals that create hermetic, gas-tight joints between glass and metal. It is growing due to increasing demand in sectors like aerospace, medical devices, automotive, and electronics, driven by advancements in technology and high-performance sealing requirements.

Conclusion

As industries in the Asia Pacific region continue to innovate and evolve, the demand for glass-to-metal seals will grow across various sectors. These seals are essential for ensuring the reliability, longevity, and safety of components used in harsh environments. With numerous high-quality manufacturers and suppliers in the region, businesses can find tailored solutions that meet their specific needs. By choosing a reputable supplier like Spcera, companies can ensure that their glass-to-metal seals provide optimal performance and value for years to come.