What Is Glass Preform?

Release time:2025-12-17

Glass preforms are small, shaped pieces of glass used as the initial step in creating finished glass products, particularly in industries requiring precise and complex shapes. They are made from materials like soda-lime, borosilicate, and quartz glass and are produced through various techniques such as blow molding, extrusion, and pressing. Glass preforms play a crucial role in applications such as packaging, electronics, and medical devices.

Understanding glass preforms

-Definition of glass preform

-Basic structure

-Materials used

What is glass preform manufacturing process?

-How to make glass preform?

-Various techniques for producing glass preforms

Types of Glass Preforms

-Standard Glass Preforms

-Specialized Glass Preforms

-Glass Preforms for Hermetic Sealing

Applications of glass preforms in hermetically sealed glass

-Use in glass-to-metal seals

-Applications in kovar sealing glass

-Utilization in iron sealing glass

SPCERA : Choosing the right glass preform for your application

Understanding Glass Preforms

Definition of Glass Preform

A glass preform is a small, shaped piece of glass that is created as an initial step in the production of finished glass products. Preforms are often used in industries where precise, complex glass shapes are required. They serve as the foundation for creating final products such as optical fibers, containers, and glass-metal seals. Glass preforms are typically heated and molded into the desired final shape through processes like blow molding or extrusion.

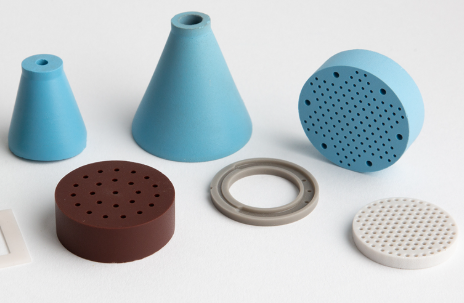

Basic Structure

The basic structure of a glass preform is typically cylindrical or spherical, though it can vary depending on its intended use. Preforms are made with precision to ensure they can be transformed into the final product with minimal waste and maximum efficiency. Their design often includes specific dimensions, wall thickness, and surface texture, which are essential for their application, particularly in specialized industries like electronics, medical devices, and automotive components.

Materials Used

Various types of glass are used in the creation of preforms, depending on their application. Common materials include:

1.Soda-Lime Glass: The most common type of glass, used for general-purpose applications such as containers and packaging.

2.Borosilicate Glass: Known for its resistance to thermal shock and chemical corrosion, commonly used in scientific and medical applications.

3.Quartz Glass: Extremely resistant to heat, making it ideal for optical fibers and high-precision devices.

4.Lead Glass: Often used for applications requiring optical clarity, such as lenses and high-end optical components.

What is the Glass Preform Manufacturing Process?

How to Make Glass Preform?

The production of a glass preform typically involves the following steps:

1.Raw Material Preparation: Glass preforms begin with the selection of raw materials, which may include silica, soda, lime, or other specialized compounds depending on the type of glass being made.

2.Melting: The raw materials are heated to high temperatures (usually above 1,000°C) to form a molten glass.

3.Shaping: The molten glass is shaped into the preform using various methods such as blow molding, extrusion, or pressing. The preform is then cooled and hardened, ensuring that it retains its shape.

4.Annealing: After shaping, the preform is annealed, a process where it is slowly cooled to relieve internal stresses and ensure uniform strength throughout the glass.

5.Finishing: The preform is then finished to meet the required specifications. This may involve additional processes such as polishing, cutting, or applying coatings to enhance its performance in the final application.

Various Techniques for Producing Glass Preforms

Several techniques are employed in producing glass preforms, depending on the end use of the preform and the required precision:

1.Blow Molding: A common method for creating hollow preforms, especially for bottles and containers. The molten glass is blown into a mold to form the desired shape.

2.Extrusion: Molten glass is forced through a die to create long, continuous shapes like rods or tubes. This is often used in applications like optical fibers and medical devices.

3.Pressing: The glass is placed into a mold and pressed into shape, which is commonly used for preforms intended for sealing applications like glass-to-metal seals.

4.Casting: Molten glass is poured into a mold to form a solid preform. This is typically used when complex shapes or intricate designs are required.

Types of Glass Preforms

Standard Glass Preforms

Standard glass preforms are generally used in common applications such as packaging, where basic shapes and sizes are needed. These preforms are typically made from soda-lime glass and can be used to create bottles, jars, and other simple glass products. These preforms are mass-produced and often require little customization.

Specialized Glass Preforms

Specialized glass preforms are designed for more advanced applications that require specific properties such as resistance to heat, chemicals, or high pressure. Preforms made from borosilicate glass or quartz are commonly used in industries like scientific research, medical equipment, and high-tech manufacturing. These preforms are customized to meet specific industry standards and are typically produced in smaller quantities with higher precision.

Glass Preforms for Hermetic Sealing

Glass preforms for hermetic sealing are used in industries where a perfect airtight seal is essential. These preforms are designed to create glass-metal seals that are critical in electronics, aerospace, and medical devices. Hermetic sealing involves sealing sensitive components in a way that prevents the ingress of moisture, air, or contaminants, ensuring the reliability and performance of the device over time. Glass preforms used in this application are often made from materials like borosilicate or lead glass, which provide excellent sealing capabilities and can withstand extreme temperatures and pressures.

Applications of Glass Preforms in Hermetically Sealed Glass

Use in Glass-to-Metal Seals

Glass-to-metal seals are essential in various industries, particularly electronics and aerospace, where airtight and durable connections are needed between glass and metal components. Glass preforms are used to create these seals, ensuring that the glass component fuses securely to the metal part. The glass preform is placed in the metal housing, and then heated to create a reliable, hermetic seal that is resistant to environmental factors. These seals are used in applications such as vacuum tubes, electronic packages, and sensor housings, where maintaining a stable internal environment is crucial.

Applications in Kovar Sealing Glass

Kovar sealing glass is a specialized glass that is used in conjunction with Kovar alloy, a metal that has a similar thermal expansion rate as glass. This makes it ideal for creating hermetic seals in high-performance applications like electronics and aerospace. Glass preforms are used in the production of Kovar sealing glass, where the preform is heated and fused with the metal to form a reliable seal. These seals are commonly used in vacuum environments and other high-stress applications, ensuring the integrity and longevity of the sealed components.

Utilization in Iron Sealing Glass

Iron sealing glass is commonly used in applications that require sealing between glass and iron. This type of glass is particularly useful in industries where cost-efficiency is a priority, such as automotive and electronics. Glass preforms used in iron sealing are often produced through pressing or extrusion methods and are designed to withstand high temperatures and pressures. Once heated and fused with the iron, the result is a strong, airtight seal that protects sensitive components from external elements.

SPCERA: Choosing the Right Glass Preform for Your Application

When selecting a glass preform for a specific application, it is important to consider several factors:

1.Material Properties: The choice of material (soda-lime, borosilicate, quartz, etc.) will depend on the desired characteristics such as thermal resistance, clarity, and chemical durability.

2.Design and Size: The preform must be tailored to fit the specific dimensions and shape required by the final product. For example, a preform used for hermetic sealing will need to fit precisely into the metal casing to create an effective seal.

3.Application Requirements: Different industries have unique needs. For instance, electronics may require preforms that can withstand extreme temperatures, while medical devices may require biocompatible materials that meet stringent health and safety standards.

At SPCERA, we offer a wide range of glass preforms tailored to meet the specific needs of various industries. Our preforms are designed to ensure the highest level of performance, reliability, and customization for any application.

Conclusion

Glass preforms are essential components in many industries, serving as the building blocks for a wide range of glass products. From glass-to-metal seals to Kovar sealing glass and iron sealing glass, these preforms ensure that the final product is durable, reliable, and hermetically sealed. Understanding the manufacturing process, material types, and specific applications of glass preforms is crucial when selecting the right preform for your needs. As technology continues to evolve, glass preforms will remain a key component in ensuring the success of many high-performance applications.