How to make hermetic seal:A Comprehensive Guide to Hermetic Solutions

Release time:2025-09-10

Hermetic sealing is essential for ensuring the integrity and durability of devices in numerous industries. From batteries to electronics, understanding the hermetic sealing process, materials, and applications is key to achieving high-performance, long-lasting solutions. In this article, we will delve into the history, principles, materials, and applications of hermetic seals, as well as factors affecting seal performance and how to customize sealing solutions, particularly through SPcera Seal manufacturers.

what is a hermetic sealing?

-The History of Hermetic Seals

-Basic principles of hermetic sealing

how to craft hermetically sealed?

-What material is used for hermetic seals?

-What is the hermetic sealing process?

What are the application scenarios of seals?

-glass preforms for hermetically seal

-Steatite Ceramic for hermetic seals

-battery terminal glass to metal seal for hermetic sealing

What are the factors that affect seals?

-Why does seal failure happen?

-Questions to Ask When Considering Seal Design and Material Selection

What is the hermetic solutions group?

How to customize sealing solutions:Spcera Seal manufacturers

Conclusion

What is a Hermetic Sealing?

The History of Hermetic Seals

Hermetic sealing dates back centuries but gained significant attention during the industrial revolution. Initially, it was applied to protect sensitive materials from environmental factors like moisture, air, and contaminants. Over time, as technology advanced, hermetic seals were integrated into more complex devices such as electronics, medical devices, and aerospace technologies. Today, hermetic sealing has become a critical aspect of ensuring the reliability of many high-precision systems.

Basic Principles of Hermetic Sealing

A hermetic seal is a barrier that completely isolates an internal component from its external environment. The key principle behind hermetic sealing is the creation of a vacuum-tight seal that prevents the entry of gases, liquids, and contaminants, while also protecting internal systems from external conditions such as humidity, temperature fluctuations, and chemical exposure.

To achieve hermetic sealing, specific materials, techniques, and processes are required. The strength and durability of the seal depend on the choice of material, the sealing method, and the application in which the seal is used.

How to Craft Hermetically Sealed?

What Material is Used for Hermetic Seals?

The material used for hermetic seals plays a crucial role in the quality and longevity of the seal. Common materials include:

Glass: Glass-to-metal seals are among the most commonly used types of hermetic seals, providing excellent chemical and electrical isolation. They are widely used in medical devices, electrical components, and space technology.

Metals: Metals like stainless steel and titanium offer exceptional mechanical strength and are commonly used in situations where high durability is required. They are often used in aerospace and military applications.

Ceramics: Steatite and alumina ceramics are popular in hermetic sealing due to their excellent thermal stability, electrical insulation properties, and resistance to corrosion.

Polymers: For less demanding applications, high-performance polymers can provide adequate sealing. They are often used for lower-pressure seals but can still offer hermetic protection in less critical environments.

What is the Hermetic Sealing Process?

The hermetic sealing process generally involves a few key stages, depending on the materials and application. The most common process for hermetic sealing includes:

Preparation of Components: The first step is ensuring that the materials and components are clean and free from contaminants. Any dirt or residue can weaken the seal's effectiveness.

Assembly: After preparation, the components (such as metal and glass or metal and ceramic) are brought together in the correct alignment.

Sealing: Heat is applied to bond the materials. For glass-to-metal seals, for instance, the glass is melted and sealed around the metal at high temperatures, creating a strong, airtight connection.

Testing: Once sealed, the assembly is tested for leaks. Methods like helium leak detection or vacuum testing ensure that the seal has been achieved successfully.

What are the Application Scenarios of Seals?

Hermetic seals are employed in a variety of industries, each requiring a different set of materials and sealing techniques. Here are some common application scenarios:

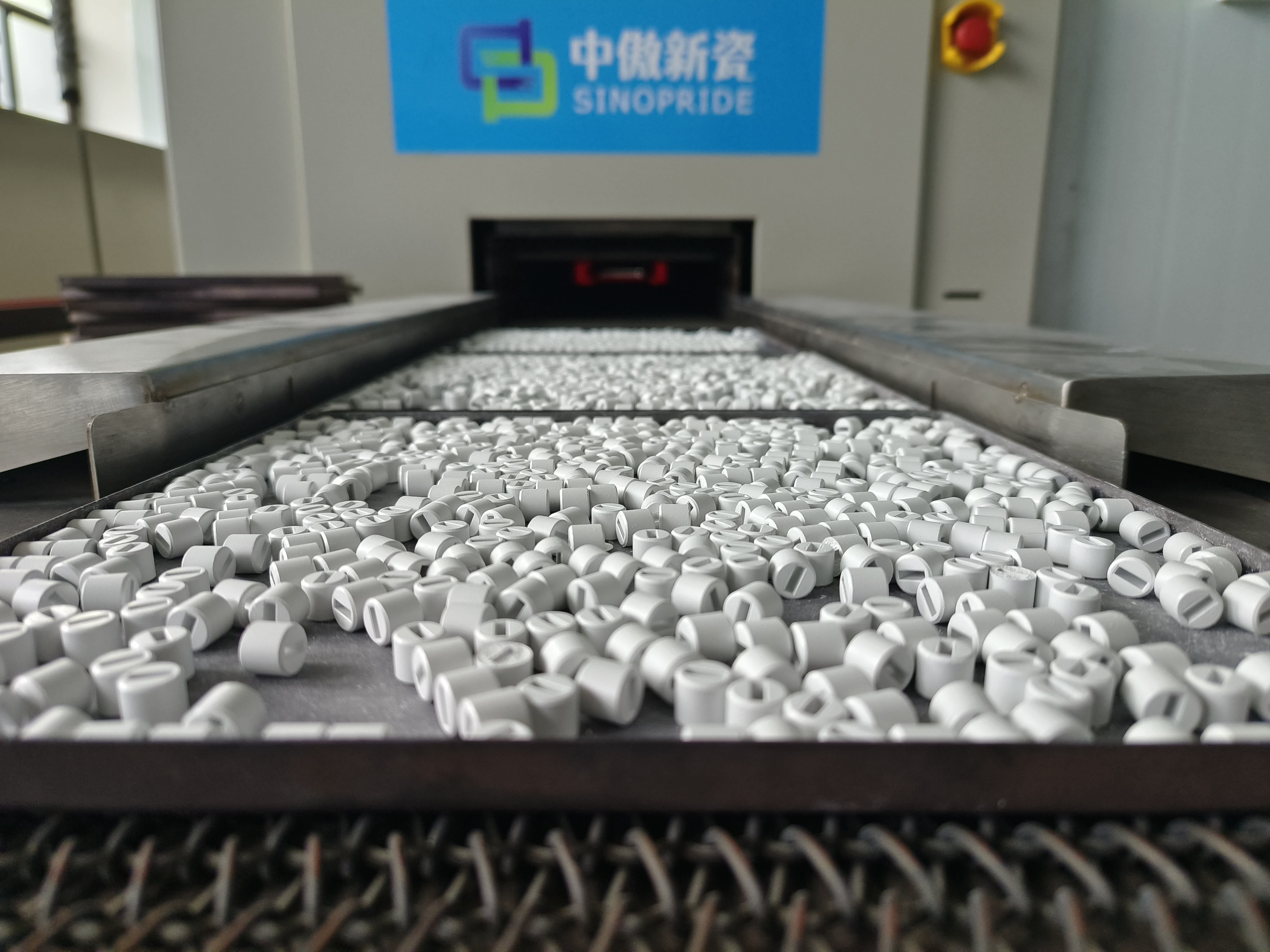

Glass Preforms for Hermetically Sealed Devices

Glass preforms are widely used in hermetic sealing, particularly in applications involving electrical components or medical devices. The process involves forming a piece of glass into a shape that can be heated and sealed to a metal or ceramic part. This method is often used for sealing electronics, such as semiconductors, lasers, and vacuum tubes, where electrical insulation and environmental protection are essential.

Steatite Ceramic for Hermetic Seals

Steatite ceramic is a popular material for creating hermetic seals in devices that operate under high-temperature or high-stress conditions. Steatite’s ability to withstand thermal and electrical stresses makes it ideal for use in the automotive, aerospace, and telecommunications industries. It is also commonly used in applications like sensor housings and capacitor assemblies, where it helps ensure long-lasting protection.

Battery Terminal Glass-to-Metal Seal for Hermetic Sealing

Glass-to-metal sealing is a popular choice for battery terminals and high-energy devices. In these applications, a glass seal provides an airtight, watertight seal around the metal components, helping to prevent leakage of gases or liquids. It is often used in devices like rechargeable batteries, medical implants, and sensors that require both electrical connection and environmental protection.

What are the Factors that Affect Seals?

Several factors can affect the performance and reliability of hermetic seals. Understanding these factors is critical for achieving long-lasting, efficient seals.

Why Does Seal Failure Happen?

Seal failure can occur for a variety of reasons:

Material Compatibility: If the materials used in the seal are incompatible, such as mismatched coefficients of expansion, this can cause the seal to weaken or break over time.

Temperature Fluctuations: Extreme temperatures can cause materials to expand and contract, leading to stress on the seal and potential failure.

Contamination: Dirt, moisture, or other contaminants during the sealing process can compromise the effectiveness of the seal, leading to leaks or premature failure.

Manufacturing Defects: Issues during the manufacturing process, such as improper alignment, insufficient heat, or inconsistent materials, can result in defective seals.

Questions to Ask When Considering Seal Design and Material Selection

When designing hermetic seals or selecting materials, several important questions need to be addressed:

1.What environmental factors will the seal be exposed to?

2.What level of sealing is required (i.e., total air and moisture exclusion, or just limited exposure)?

3.What mechanical stresses will the seal need to withstand?

4.What are the long-term durability requirements of the application?

5.Are there any special electrical or thermal conductivity needs?

Considering these questions will help guide the material selection and sealing process to ensure the best performance.

What is the Hermetic Solutions Group?

The Hermetic Solutions Group (HSG) is a leading provider of hermetic sealing technologies. Specializing in glass-to-metal, glass-to-ceramic, and other advanced sealing techniques, HSG supports industries such as aerospace, automotive, telecommunications, and medical devices. Their expertise helps ensure that high-performance seals are used in critical applications, from power electronics to sensors and beyond.

How to Customize Sealing Solutions: SPCERA Seal Manufacturers

Customizing a sealing solution requires a deep understanding of the application’s specific needs. SPCERA Seal manufacturers offer tailored sealing solutions, ensuring that the materials and processes used align perfectly with the requirements of each project. Whether you need glass-to-metal, glass-to-ceramic, or other hermetic sealing methods, SPCERA Seal manufacturers can provide expert design, material selection, and high-quality production to meet your specifications.

Conclusion

Hermetic seals are indispensable in protecting sensitive components and systems in various industries. By understanding the materials, processes, and factors that influence hermetic sealing, manufacturers can ensure the longevity and performance of their products. Whether for medical devices, aerospace technologies, or consumer electronics, selecting the right hermetic sealing solution is crucial. Working with trusted manufacturers like SPcera Seal can help you customize the perfect solution for your sealing needs, ensuring high performance and reliability for years to come.

Recommended Reading

1.What is Glass-to-Metal Hermetic Seals Solution:Hermetically sealed connectors

2.What does hermetically sealed mean?

3.Exploring 2025 Glass Hermetic Seal Materials: Types, Benefits, and Manufacturers