Characteristics and Applications of Steatite Ceramics

Release time:2025-08-29

Steatite ceramics are high-performance materials known for their exceptional electrical insulation, thermal stability, and high-temperature resistance. These properties make them widely used in electronics, electrical, and high-temperature industrial applications. This article will explore the composition, production process, performance characteristics, and applications of steatite ceramics, with a special focus on how SINOPRIDE steatite ceramics stand out in the market for their excellent cost-performance ratio.

What is steatite ceramic?

-Composition of Steatite Ceramics

-Market price of talc ceramic beads

-The Difference Between Talc and Soapstone

The Production process of talc ceramics

Performance characteristics of talc ceramics

-Steatite insulator ceramics

-High-performance steatite ceramics

-Refractory steatite ceramics

Application of steatite ceramics

-Application of Steatite Ceramic Bead

-Application of Ceramic Steatite Insulator

Design & Reliability Strategies for Hermetic Seal Performance

-Hermetic seal architecture for reliability (joint geometry, seal length, stress-relief design)

-Material matching for Unmatched Hermetic Seals (CTE fit, wetting/adhesion, metallization compatibility)

- Process controls to protect seal integrity (surface prep, brazing profile, atmosphere & cleanliness)

- Reliability verification for ceramic-to-metal seals (He leak, thermal cycling, humidity/pressure aging, shock & vibration)

- Failure modes & prevention (microcracks, delamination, corrosion paths, glass/braze porosity)

Conclusion and SINOPRIDE Steatite Ceramics’ Cost-Performance Advantage

What is Steatite Ceramic?

Steatite ceramic is an inorganic ceramic made primarily from the mineral steatite (chemical formula: Mg₃Si₄O₁₀(OH)₂). Steatite itself contains a high level of magnesium and has a unique layered structure, which imparts excellent electrical insulation, thermal stability, and high-temperature resistance to steatite ceramics. These ceramics are commonly used in applications requiring high voltage and high-temperature resistance and are indispensable in many modern technologies.

Composition of Steatite Ceramics

The primary component of steatite ceramics is steatite mineral, which is known for its low thermal expansion coefficient and superior electrical insulation properties. In addition to steatite, these ceramics often include minor amounts of alumina, quartz, and other additives to enhance their mechanical strength, thermal shock resistance, and corrosion resistance. By adjusting the mixture and using precise production methods, steatite ceramics can be tailored to meet the requirements of various applications.

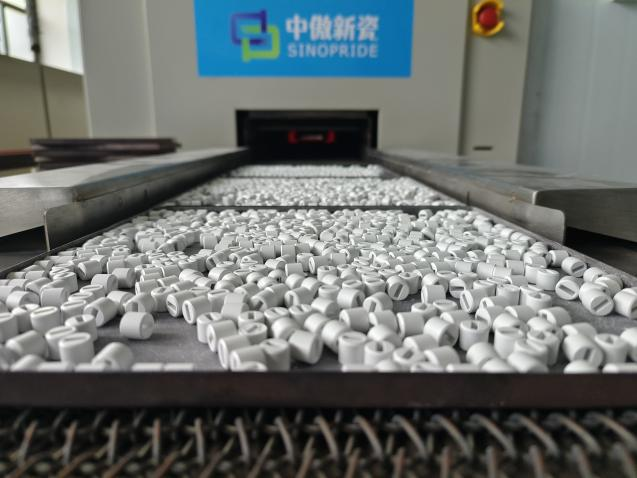

Market Price of Steatite Ceramic Beads

The price of steatite ceramic beads varies based on factors such as the purity of the raw materials, the production process, and market demand. High-quality steatite ceramic beads generally command higher prices due to their excellent electrical insulation and high-temperature resistance. However, over the long term, these beads often provide a higher cost-performance ratio due to their durability and stability. In particular, for electronic components and electrical insulation applications, steatite ceramic beads can significantly extend the service life of equipment.

The Difference Between Steatite and Soapstone

While both steatite (talc) and soapstone contain the same mineral, steatite, they differ in terms of their applications and physical properties. Steatite is typically a powder-like material used in ceramics, cosmetics, plastics, and similar fields, whereas soapstone is a denser metamorphic rock made of steatite, mica, and dolomite. Soapstone is more easily processed and is known for its higher heat resistance. Although there is some overlap in applications, steatite ceramics are more commonly used in high-end technology fields where excellent electrical insulation and thermal stability are required.

The Production Process of Steatite Ceramics

The production process of steatite ceramics involves several key steps to ensure high-quality and consistent materials:

Raw Material Selection: High-purity steatite powder is selected and mixed with alumina, quartz, and other additives to achieve the desired composition.

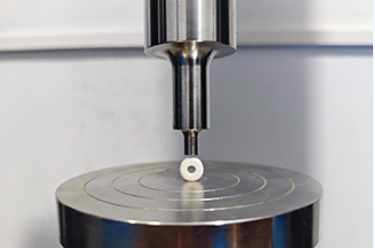

Shaping: Depending on the final product’s shape, the raw materials are molded through pressing, injection molding, or extrusion. Precise control of temperature and pressure is required to ensure uniformity across batches.

Firing: The shaped ceramic pieces are then fired in a high-temperature kiln, typically at temperatures ranging from 1000°C to 1400°C. This step removes moisture and impurities, resulting in a strong, stable ceramic structure.

Cooling and Post-processing: After firing, the ceramic materials are slowly cooled to avoid thermal stress cracks. They are then polished, cut, or otherwise post-processed to ensure they meet the required specifications.

Performance Characteristics of Steatite Ceramics

Steatite ceramics offer a range of outstanding properties that make them suitable for use in electronics, electrical, and high-temperature environments. Below are some of the key performance characteristics:

Steatite Insulator Ceramics

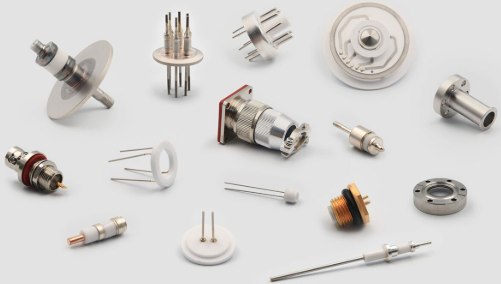

Steatite ceramics are known for their extremely high electrical insulation performance, making them the preferred material for electrical insulation components. These ceramics effectively isolate electrical current, preventing short circuits or failures in electrical equipment. As a result, steatite ceramics are widely used in high-voltage devices, power cables, sensors, and similar applications.

High-Performance Steatite Ceramics

High-performance steatite ceramics not only possess excellent electrical insulation but also demonstrate exceptional thermal stability, compression strength, and corrosion resistance. These materials are used in high-demand applications, such as high-voltage electrical equipment, spacecraft, and electronic components. Their outstanding heat resistance enables them to remain stable even in extreme temperature environments.

Refractory Steatite Ceramics

Refractory steatite ceramics are designed to maintain structural stability at high temperatures. These ceramics are commonly used in industries such as metallurgy, steelmaking, and high-temperature furnaces. They offer excellent thermal shock resistance, allowing them to withstand large temperature fluctuations without cracking or degrading. This makes them highly valuable for improving the safety and durability of high-temperature industrial equipment.

Applications of Steatite Ceramics

Application of Steatite Ceramic Beads

Steatite ceramic beads are widely used in the electronics, electrical, and automotive industries. In electrical devices, steatite ceramic beads are commonly used to manufacture electrical components, sensors, circuit protectors, and more. These beads provide excellent electrical insulation and high-temperature resistance, allowing them to perform reliably even in harsh environments.

Application of Steatite Ceramic Insulators

Steatite ceramics are commonly used as electrical insulator materials in high-voltage equipment. Their superior electrical properties, thermal stability, and mechanical strength make them essential in applications such as power generation and transmission, communication devices, and other high-voltage sectors. Steatite ceramics are also utilized in automotive electronics, solar power devices, and similar industries that require reliable electrical insulation and high-temperature performance.

Design & Reliability Strategies for Hermetic Seal Performance

Hermetic seal architecture for reliability (joint geometry, seal length, stress-relief design)

A reliable hermetic seal starts with geometry that keeps the ceramic in compression and minimizes stress concentration at edges. Designers typically favor symmetric joints, generous fillets, and controlled overlap/land widths to distribute load uniformly. Seal length (effective bonding area) should be sufficient to resist peel forces and accommodate thermal cycling, but not so large that it traps residual stress. Stress-relief features—such as compliant interlayers, graded transitions, or relief grooves—help buffer the CTE mismatch between metal and steatite, reducing the risk of crack initiation at the ceramic edge or braze meniscus.

Material matching for Unmatched Hermetic Seals (CTE fit, wetting/adhesion, metallization compatibility)

To achieve Unmatched Hermetic Seals, the ceramic–metal pair must be engineered as a system. First, select metals/alloys with a compatible coefficient of thermal expansion (CTE) to steatite to limit residual tensile stress after cooling. Second, ensure the sealing material (braze alloy or glass) properly wets both surfaces; poor wetting leads to voids and leak paths even if the joint “looks” bonded. Third, metallization compatibility matters: steatite often relies on a metallized layer (e.g., Mo/Mn + Ni plating, or other suitable metallization stacks) to promote adhesion and wetting during brazing. A stable metallization stack also reduces interfacial reactions that can embrittle the joint over time.

Process controls to protect seal integrity (surface prep, brazing profile, atmosphere & cleanliness)

Even with the right design, process drift is a common reason hermetic seals fail. Surface preparation should remove oils, particulates, and weak surface films; controlled roughness improves mechanical interlocking but excessive roughness can trap contaminants and create micro-voids. Brazing profiles must be tuned to the ceramic/metal mass and joint design—insufficient soak limits flow and wetting, while excessive temperature/time can thicken reaction layers and increase brittleness. Atmosphere control (vacuum, inert, or reducing environment) prevents oxidation and supports consistent wetting. Cleanliness is non-negotiable: small residues can outgas during sealing and form porosity, creating latent leaks that appear after thermal cycling.

Reliability verification for ceramic-to-metal seals (He leak, thermal cycling, humidity/pressure aging, shock & vibration)

Verification should prove both initial and life-cycle performance of the hermetic seal. Helium leak testing is the standard screening tool to confirm gas tightness and detect micro-leaks early. Thermal cycling validates resistance to CTE-driven fatigue, often revealing edge cracking or interfacial debonding that a room-temperature leak test can miss. Humidity/pressure aging targets corrosion-driven leak paths and glass/braze degradation under combined moisture and stress. Shock and vibration screening confirms mechanical robustness for transport, aerospace, automotive, and industrial duty—especially where the seal also carries structural load or is integrated into high-voltage assemblies.

Failure modes & prevention (microcracks, delamination, corrosion paths, glass/braze porosity)

Common failure modes typically trace back to stress, chemistry, or defects. Microcracks often initiate at sharp ceramic corners or braze menisci—prevent with stress-relief geometry, better CTE matching, and controlled cooling rates. Delamination indicates weak adhesion or unstable metallization; improve surface prep, metallization quality, and wetting behavior. Corrosion paths form when moisture penetrates along interfaces or through micro-porosity—use corrosion-resistant alloys/platings, ensure dense seals, and avoid flux residues. Glass/braze porosity is frequently caused by contamination, outgassing, or improper thermal profiles—tighten cleanliness controls, optimize firing/brazing parameters, and verify with sectioning/CT or metallography during process qualification.

Conclusion and SINOPRIDE Steatite Ceramics’ Cost-Performance Advantage

SINOPRIDE steatite ceramics, manufactured using high-quality raw materials and advanced production techniques, offer exceptional performance across various applications. These ceramics demonstrate excellent electrical insulation, high-temperature resistance, and mechanical strength, making them ideal for use in electronics, electrical, and high-temperature industries. With their outstanding performance and competitive pricing, SINOPRIDE steatite ceramics provide an excellent cost-performance ratio. For customers seeking high-quality materials at an affordable price, SINOPRIDE steatite ceramics represent the best choice in the market.