Technical Ceramics Explained: An Introduction Including Steatite Ceramic

Release time:2026-01-31

Technical ceramics are advanced engineering materials designed for demanding applications where plastics or metals may fail—especially under heat, electrical stress, corrosion, or wear. This introduction explains what technical ceramics are, how they differ from non-technical ceramics, and what they are used for across industries. The article focuses on steatite ceramic, a widely used and cost-effective electrical insulator known for stable performance, reliable thermal expansion behavior, and strong manufacturability for precision components such as ceramic steatite insulators and steatite beads.

What is technical ceramics?

-Definition (simple, science-friendly)

-Technical ceramic products: what counts as“technical”?

-Key performance properties engineers care about (mini checklist)

What is steatite ceramic?

-Steatite ceramic explained (what it is, why it’s used)

-Steatite ceramic properties (based on real specification-style data)

-Ceramic steatite insulator: why steatite is a classic electrical material

What is the difference between technical and non technical ceramics?

-Technical vs traditional ceramics (clear, beginner-friendly comparison)

-Why this difference impacts cost, lead time, and consistency

What are technical ceramics used for?

-Application map (by industry)

-Where Steatite Ceramic fits best (positioning section)

Steatite vs Other Technical Ceramics (Selection Guide)

-Steatite Ceramic vs Alumina vs Zirconia (practical decision comparison)

-“Rule-of-thumb” selection flow

Steatite Ceramic in Real Products

-Common technical ceramic products made from steatite

-Design notes engineers appreciate (practical tips)

Pricing & Buying: How to Evaluate “Best Steatite Ceramic Bead Price” (Without Sacrificing Quality)

-What drives the best steatite ceramic bead price?

-Quote checklist (what to ask suppliers for)

What is technical ceramics?

Definition (simple, science-friendly)

Technical ceramics (also called engineering ceramics or advanced ceramics) are ceramic materials engineered for functional performance rather than decoration. Unlike traditional ceramics used for tiles or dinnerware, technical ceramics are produced with controlled raw materials, precise forming methods, and carefully managed sintering (firing) processes to achieve repeatable mechanical, thermal, and electrical properties.

In practical terms, technical ceramics are chosen when an application requires one or more of the following:

1.Electrical insulation at high temperature

2.Dimensional stability under thermal cycling

3.Wear resistance in harsh environments

4.Chemical corrosion resistance

5.High hardness and long service life

Technical ceramic products: what counts as “technical”?

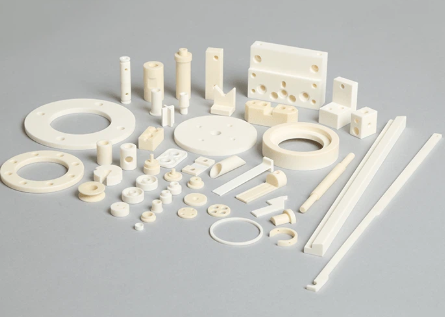

A good way to understand technical ceramics is to look at real products. Common technical ceramic products include:

1.Electrical insulators (feedthroughs, terminal blocks, standoffs)

2.Ceramic beads and sleeves for wire insulation or heaters

3.Connector structural components and spacers

4.Sensor supports and precision fixtures

5.Wear parts (seals, nozzles, bushings, guides)

6.Substrates for electronics (depending on material)

These parts are often used in electronics, energy systems, industrial equipment, and automotive components, where consistent performance matters more than appearance.

Key performance properties engineers care about (mini checklist)

When engineers evaluate technical ceramics, they typically focus on a short list of performance indicators:

1.Electrical properties: insulation resistance, dielectric strength, stability over temperature

2.Thermal properties: coefficient of thermal expansion (CTE), thermal conductivity, thermal shock behavior

3.Mechanical properties: bending strength, hardness, reliability under stress

4.Environmental performance: resistance to chemicals, humidity, and long-term aging

5.Manufacturability: ability to hold tolerances, consistency across production batches

This is why “technical ceramics market” demand continues to grow—modern devices and infrastructure require materials that don’t drift, deform, or degrade under real-world stress.

What is steatite ceramic?

Steatite ceramic explained (what it is, why it’s used)

Steatite ceramic is a magnesium silicate–based technical ceramic widely known for electrical insulation and stable thermal behavior. It has been used for decades in electrical and industrial systems because it offers a strong balance of performance and cost.

Why engineers select steatite ceramic:

1.Excellent electrical insulation for many common voltage ranges

2.Stable thermal expansion (helps protect assemblies from stress during heating/cooling)

3.Good surface finish and reliable shaping for mass-produced parts

4.Cost-effective compared to some higher-purity advanced ceramic families

For many applications, steatite is the practical “workhorse” ceramic—especially when the goal is reliable insulation rather than extreme mechanical strength.

Steatite ceramic properties (based on real specification-style data)

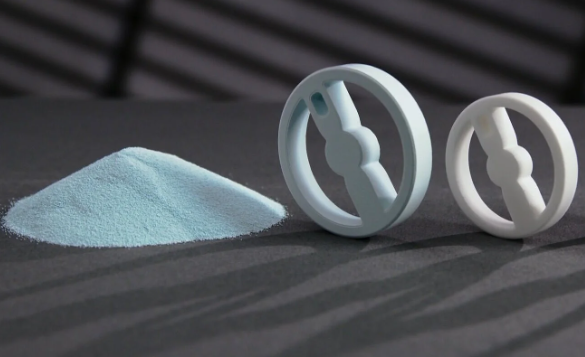

Below is an example specification-style dataset for a steatite ceramic grade used in precision connector components. This style of table is helpful for engineering communication because it ties properties to an application and grade code.

|

Application Example |

Code |

Composition |

Density (g/cm³) |

Bending Strength |

CTE (30–300°C) ×10⁻⁶/K |

Color Options |

|

Connector structural component |

CM083 |

Steatite ceramics |

2.85 |

~150 MPa |

8.0 ± 0.5 |

White, light blue, green, grey |

How to read this table (buyer + engineer viewpoint):

1.Density helps indicate compactness and consistency of the sintered body.

2.Bending strength gives a practical measure for part durability in handling and assembly.

3.CTE matters when steatite parts interface with metals or other ceramics—matching CTE reduces cracking risk during thermal cycling.

4.Color options are often tied to composition and process; color itself is usually not a performance indicator unless specified for identification.

Ceramic steatite insulator: why steatite is a classic electrical material

A ceramic steatite insulator is commonly used anywhere electrical isolation is required with added benefits such as heat resistance and dimensional stability. Steatite remains popular in insulating components because it performs reliably under elevated temperatures and maintains insulation performance where plastics may soften or carbonize.

Typical applications include:

1.Feedthrough and terminal insulation parts

2.Connector structural insulation components

3.Heater supports and wire insulation beads

4.Spacers and sleeves for electrical separation

In many product designs, steatite plays a quiet but critical role: it reduces leakage risk, improves temperature stability, and helps assemblies survive long operating cycles.

What is the difference between technical and non technical ceramics?

Technical vs traditional ceramics (clear, beginner-friendly comparison)

The biggest difference is purpose. Traditional ceramics are often selected for appearance and basic function, while technical ceramics are selected for measurable engineering performance.

|

Category |

Technical Ceramics |

Non-Technical Ceramics |

|

Goal |

Performance + reliability |

Aesthetics + basic function |

|

Tolerances |

Tight |

Moderate/loose |

|

Testing |

Standardized, repeatable |

Limited/varies |

|

Materials |

Alumina, steatite, zirconia, SiC, etc. |

Clay-based, feldspar, glaze systems |

|

Typical Uses |

Electronics, industrial, automotive |

Construction, homeware |

Why this difference impacts cost, lead time, and consistency

Because technical ceramics target reliable engineering performance, the manufacturing system must control:

1.raw material purity and batch consistency

2.forming method repeatability

3.sintering curve stability and shrinkage control

4.inspection standards (dimensions, defects, and sometimes electrical tests)

This affects cost and lead time, but it also reduces failure risk—especially for components like connector insulators, beads, and structural ceramic supports where a small defect can cause cracking or electrical leakage.

What are technical ceramics used for?

Application map (by industry)

Technical ceramics appear in more places than many people realize. Common industry use cases include:

1.Electronics & electrical: insulators, substrates, spacers, feedthroughs

2.Industrial systems: wear parts, seals, bushings, fixtures

3.Automotive & mobility: sensor supports, insulating components, specialty wear parts

4.Energy & heating: heater supports, insulation beads, high-temperature isolators

5.Medical & lab equipment (material-dependent): wear-resistant and chemically stable components

Where Steatite Ceramic fits best (positioning section)

Steatite ceramic fits best in applications needing:

1.reliable electrical insulation

2.stable thermal expansion behavior

3.consistent manufacturing for high-volume parts

4.a cost-effective alternative to higher-grade ceramics

In other words, steatite is ideal when the design does not require extreme hardness or ultra-high strength but still demands reliable insulation and stable performance.

Steatite vs Other Technical Ceramics (Selection Guide)

Steatite Ceramic vs Alumina vs Zirconia (practical decision comparison)

|

Material |

Typical Strengths |

Typical Limitations |

Best Use Cases |

|

Steatite Ceramic |

Cost-effective insulation, stable CTE, good surface finish |

Lower strength than high-purity alumina |

Insulators, connector parts, beads, spacers |

|

Alumina (Al₂O₃) |

High hardness, strong, widely available |

Higher cost than steatite in some grades |

Wear parts, substrates, insulators |

|

Zirconia (ZrO₂) |

High toughness |

Cost, density, certain aging behaviors |

Tough mechanical parts, impact-prone components |

Steatite stands out because it provides strong real-world value when electrical insulation is the main requirement. Alumina becomes more attractive when wear resistance and higher mechanical performance are required. Zirconia is often selected when toughness and resistance to cracking from impact matter most.

“Rule-of-thumb” selection flow

1.Need cost-effective insulation + stable thermal expansion? → Choose Steatite Ceramic

2.Need higher hardness / wear resistance / stronger structure? → Choose Alumina

3.Need toughness for impact-prone mechanical parts? → Choose Zirconia

This fast decision logic helps buyers and engineers shortlist materials early—then confirm using real property data and prototype tests.

Steatite Ceramic in Real Products

Common technical ceramic products made from steatite

Steatite is frequently used in:

1.Ceramic steatite insulator parts (feedthroughs, terminal blocks, standoffs)

2.Steatite beads (heating elements, wire insulation beads, spacers)

3.Connector structural components (like the CM083 example)

4.Sensor supports, bushings, sleeves, and small fixtures

These product forms match how steatite ceramic is typically purchased: as precision parts with controlled dimensions and stable properties rather than bulk material.

Design notes engineers appreciate (practical tips)

Good design reduces failure risk and improves production consistency:

1.Fillets reduce stress concentrations

Sharp edges can concentrate stress and lead to cracks during assembly or thermal cycling.

2.Avoid sharp internal corners

Internal corners are common crack initiation points—especially in brittle materials like ceramics.

3.Allow for shrinkage + sintering tolerances

Ceramics shrink during firing. Designs should include tolerance planning and realistic dimensional requirements.

4.Surface finish choices: as-fired vs ground/polished

As-fired surfaces are often lower cost; ground surfaces improve fit and tolerance but increase price.

Pricing & Buying: How to Evaluate “Best Steatite Ceramic Bead Price” (Without Sacrificing Quality)

What drives the best steatite ceramic bead price?

When buyers search for the best steatite ceramic bead price, the smartest approach is to evaluate total value—not just the lowest unit cost. Beads are often used in electrical heating or insulation systems, so consistency and defect control can directly affect performance.

Key cost drivers:

|

Cost Driver |

How It Changes Price |

Buyer Tip |

|

Tight tolerances |

↑ machining/inspection |

Relax tolerances where possible |

|

Complex geometry |

↑ tooling + scrap risk |

Simplify shapes for savings |

|

Surface grinding |

↑ processing time |

Use as-fired surfaces when acceptable |

|

Low volume |

↑ unit price |

Batch orders to reduce cost |

|

Special QC reports |

↑ inspection cost |

Specify only what you need |

A “cheap” bead that chips easily, varies in ID/OD, or has hidden cracks can cause expensive downstream issues—scrap, downtime, or field failures.

Quote checklist (what to ask suppliers for)

To buy confidently—especially for repeat orders—request:

1.Material grade/code and key property targets (density, strength, CTE as needed)

2.Dimensional drawing confirmation + tolerance capability

3.Inspection plan (sampling, defect criteria, measurement tools)

4.Optional: CoA, dimensional report, and traceability notes

5.Packaging method (prevents chipping during shipping)

6.Lead time, MOQ, and replacement policy for defects

Technical ceramics are engineered materials designed to deliver stable performance under demanding conditions. Among them, steatite ceramic remains one of the most practical and widely used choices for electrical insulation components thanks to its cost efficiency, stable thermal expansion, and reliable manufacturability. Whether you’re evaluating a ceramic steatite insulator, sourcing connector components like CM083-grade parts, or comparing the best steatite ceramic bead price, focusing on real specification data, fit-for-use design, and supplier quality controls will help you achieve dependable results in production and long-term use.